17. When checking the continuity of the witches

or transformer, always make sure that the

power is OFF, and one of the lead wires is

disconnected.

18. Components that are critical for safety are

indicated in the circuit diagram by

shading,

or .

19. Use replacement components that have the

same ratings, especially for flame resistance

and dielectric strength specifications. A

replacement part that does not have the

same safety characteristics as the original

might create shock, fire or other hazards.

1. High Voltage Warning

Do not attempt to measureany of the high

voltages--this includes the filament voltage

of the magnetron. High voltage is present

during any cook cycle.

Before touching any components or wiring,

always unplug the oven and discharge the

high voltage capacitor (See Figure 1-1)

2. The high-voltage capacitor remains charged

about 30 seconds after disconnection. Short

the negative terminal of the high-voltage

capacitor to to the oven chassis. (Use a

screwdriver.)

3. High voltage is maintained within specified

limits by close-tolerance, safety-related

components and adjustments. If the high

voltage exceeds the specified limits, check

each of the special components.

1-2

Pretaution

Samsung Electronics

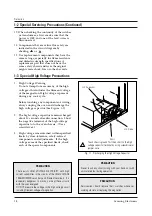

1-2 Special Servicing Precautions (Continued)

1-3 Special High Voltage Precautions

PRECAUTION

Never touch any circuit wiring with your hand nor with

uninsulated tool during operation.

H. V. Diode

Short

H. V. Capacitor

PRECAUTION

There exists HIGH VOLTAGE ELECTRICITY with high

current capabilities in the circuits of the HIGH VOLTAGE

TRANSFORMER secondary and filament terminals. It is

extremely dangerous to work on or near these circuits

with the oven energized.

DO NOT measure the voltage in the high voltage circuit

including filament voltage of magnetron.

PRECAUTION

Servicemen should remove their watches whenever

working close to or replacing the magnetron.

Fig. 1-1. Discharging the High Voltage Capacitor

Touch chassis ground first then short to the high

voltage capacitor terminal by using screwdriver or

jumper wire.