Troubleshooting _ 29

■

System Check Mode

■

TEST MODE

Power On state

(Normal user mode)

Wrinkle P

Dry Level 7 SEC

System Check Mode

Definition of Service Mode :

• - “ t2 ” will display.

• System Check Mode(t2 mode) Progress Function Performed Start/Pause Motor(CW) Relay On → Heater Relay On

→ Heater Relay Off, Motor(CW) Relay Off

How to Enter :

• While in Power Off, pressing the Dry Level + Power keys simultaneously will put the dryer into the System Check

mode.

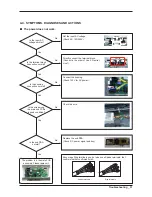

4-3. TROuBLE DIAGNOSIS

As the micom dry machine is configured for the complicate structure, there might be a service call.

The below information is prepared for exact trouble diagnosis and suitable repair guide.

■

Caution for the repair and replacement

Please follow below instruction for the trouble diagnosis and parts replacement.

1. As some electronic components can be damaged by static electricity from the resin part of dryer or the human body,

remove the potential difference of the human body and the dryer by contacting the power plug before you start

working at PCB.

Power supply plug

2. Since AC220~240V is applied to the triac T1 and T2 on P.C.B, the electric shock may occur by touching. Be careful

the strong and weak electricity are mixed each other.

3. As the P.C.B assembly is designed for no trouble, do not replace the P.C.B assembly by the wrong diagnosis and

follow the procedure of the trouble diagnosis when the micom is not operated normally.

No

Problem

What to do

1

Will Not Start or Run

•

All wires are hooked up to their corresponding terminals.

•

Is the dryer is plugged in.

•

Blown fuse or circuit breaker.

•

Is the Door switch functional...door closed. Check for error code 3 (See Table for code

definition).

•

Start/Pause rotary selector dial functional.

•

Is the control Board operational.

•

Belt off or broken and Belt Cut-off Switch operates.

•

Is the motor functional.

•

Check motor winding resistance: 2.88ohms between pin #3 and 4, 3.5ohms between pin #4

and 5.

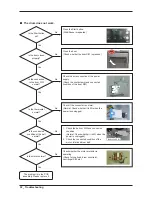

2

Motor runs/ tumbler will not

turn

•

Belt off or broken/damaged.

•

Idler tension spring too weak or stretched.

•

Idler pulley jammed or stuck.

3

Runs a few minutes and then

stops

• Lint buildup around drive motor.

• Low voltage present.

• Blower impeller blocked in blower housing.

• Check the actuator of motor.

Содержание DV448AEP

Страница 28: ...26 _ Disassembly and Reassembly memo ...

Страница 49: ...Exploded views and Parts list _ 47 memo ...

Страница 63: ...Exploded views and Parts list _ 61 memo ...

Страница 64: ...62 _ Exploded views and Parts list 5 3 Ass y Panel Control 0 1 2 4 1 3 6 3 6 2 6 1 6 4 6 5 6 5 3 5 2 5 1 5 ...

Страница 71: ...Exploded views and Parts list _ 69 memo ...

Страница 85: ...Exploded views and Parts list _ 83 memo ...

Страница 93: ...Exploded views and Parts list _ 91 memo ...

Страница 120: ...118 _ Exploded views and Parts list memo ...