6

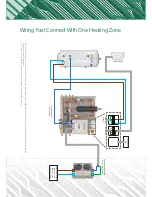

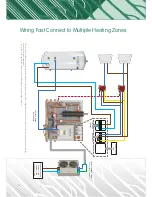

Diverter Valves

To be able to operate the unit correctly, the system will need to be

hydraulically set up so that the heating and hot water are heated individually.

This can be done with two diverter valves, one for hot water and one for

heating. These will be included within the heat pump kit.

Magnetic Dirt Filter & Filter Ball

To reduce the chances of any blockages within the heat pump and to remove

any unwanted objects, a dirt filter will need to be installed. Solfex have taken

the extra step of including a filterball into the system for extra protection.

If the filters are not installed this could void the warranty of the unit.

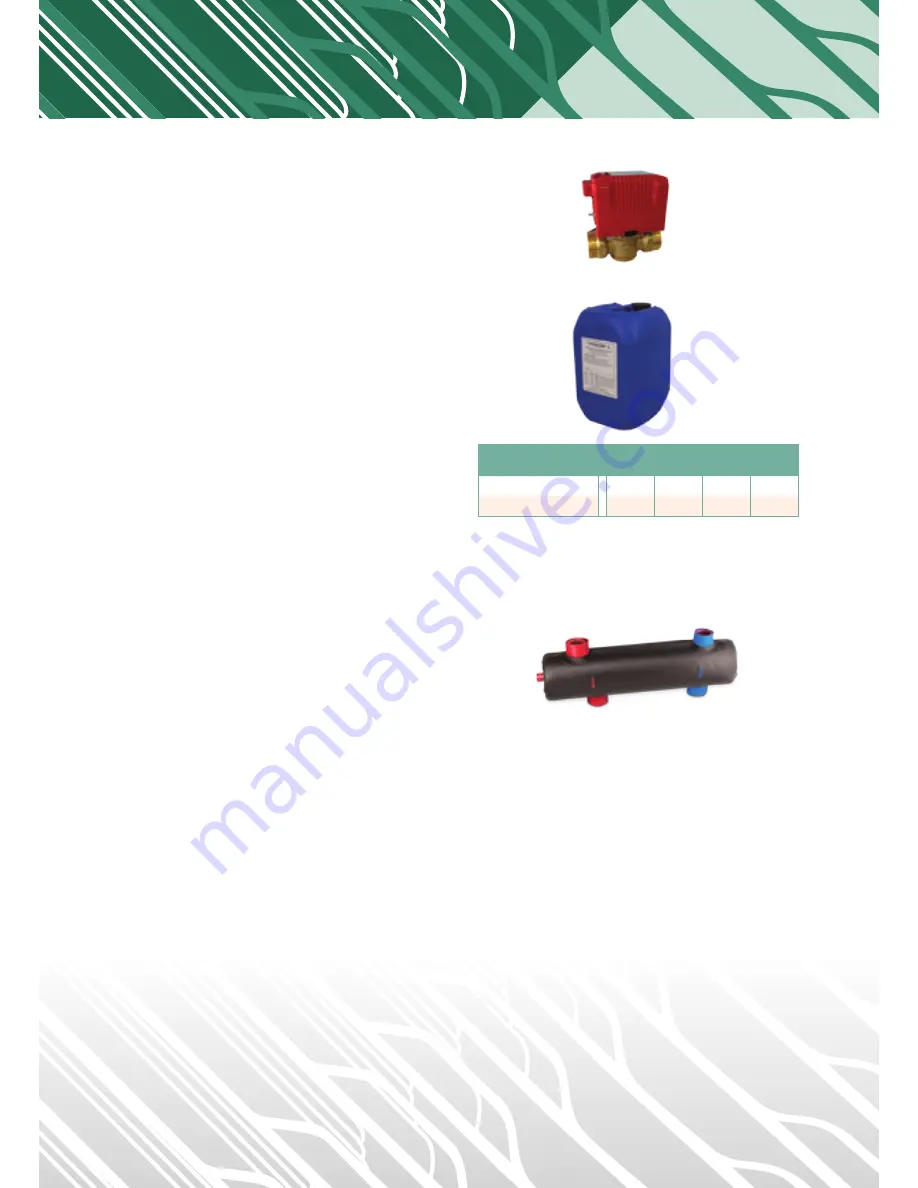

Glycol - Tyfocor L

Monobloc heat pumps are installed outdoors meaning that there is always

going to be some pipework outside. The unit has it’s own defrost function

to prevent it freezing up, however, if there is a power issue then the risk of

the unit freezing rises considerably. To prevent this, glycol will need to be

introduced into the system, it is important to measure the concentration to

make sure that the mixture is enough to protect the unit.

If the unit freezes then this will void the warranty.

A mixture of 25% is normally recommended to protect down to -10.7% for

Tyfocor L. If too much glycol is added to the system then this can cause issues

as it will require more power from the pump and will also have a negative

effect on the capacity of the unit. It is always best to mix the glycol before

introducing it into the system, this way you will avoid inconsistencies in the

viscosity of the fluid.

Hydraulic Separators

In the past all heat pumps were single speed, this meant that a buffer tank was

required as it allowed the unit to operate for longer periods of time before

having to switch back off again. In low load conditions this would prove to be

a bad situation as the unit would need to continuously switch itself on and off

again, i.e. short cycling. The introduction of an inverter driven compressor

removed this requirement. However a hydraulic separator is now used for

other things within the system.

Modulation and Inverters

The introduction of inverter driven units with variable speeds meant that the

buffer vessel is no longer a requirement for a heat pump system.

The heat pump changes the speed of the compressor to alter the output of

the heat pump, much like adjusting the gas in a boiler.

Samsung’s units can alter their output down to as low as 10% and has

removed the cycling process.

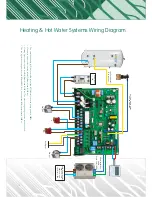

Defrost

In cold and wet weather, the outdoor unit can start to freeze up causing a sheet of ice to form on the fin coils at the back and side of the unit.

In conditions below -2°C, the coils are less likely to freeze as there is less water in the air. If a coil was to be blocked by the ice then the unit will need to run

in defrost mode. To do this it reverses the operation of the unit by using the heat from the system to heat the coils. The effect of this is that it will start to take

heat from the dhw or heating system and the temperature will start to decrease.

In worst case scenarios, the unit can enter the defrost mode for around 6 minutes every hour.

After the defrost process has complete, all of the ice will have been melted from the back of the heat pump and pour out into the drain off system.

Every time water is put through the unit it will lose up to 5°C, the flow rate will be at 20 L/m. This means that if the system volume is considerably small then

the temperature can drop dramatically. An example of this would be if there was around 20 litres within the system all of the fluid will circulate through the

unit 6 times in 6 minutes and this will cause a 30°C drop in temperature. This is where a volumiser or a buffer tank can come in handy as this will increase the

volume of fluid and also the heat will be taken from the store rather than the property.

Minimum

Outdoor Temperature

0°C

-5°C

-10°C

-15°C

Ethylene Glycol

10%

15%

25%

35%

Propylene Glycol

10%

15%

25%

35%