9

English

Ins

tallation Pr

oc

edur

e

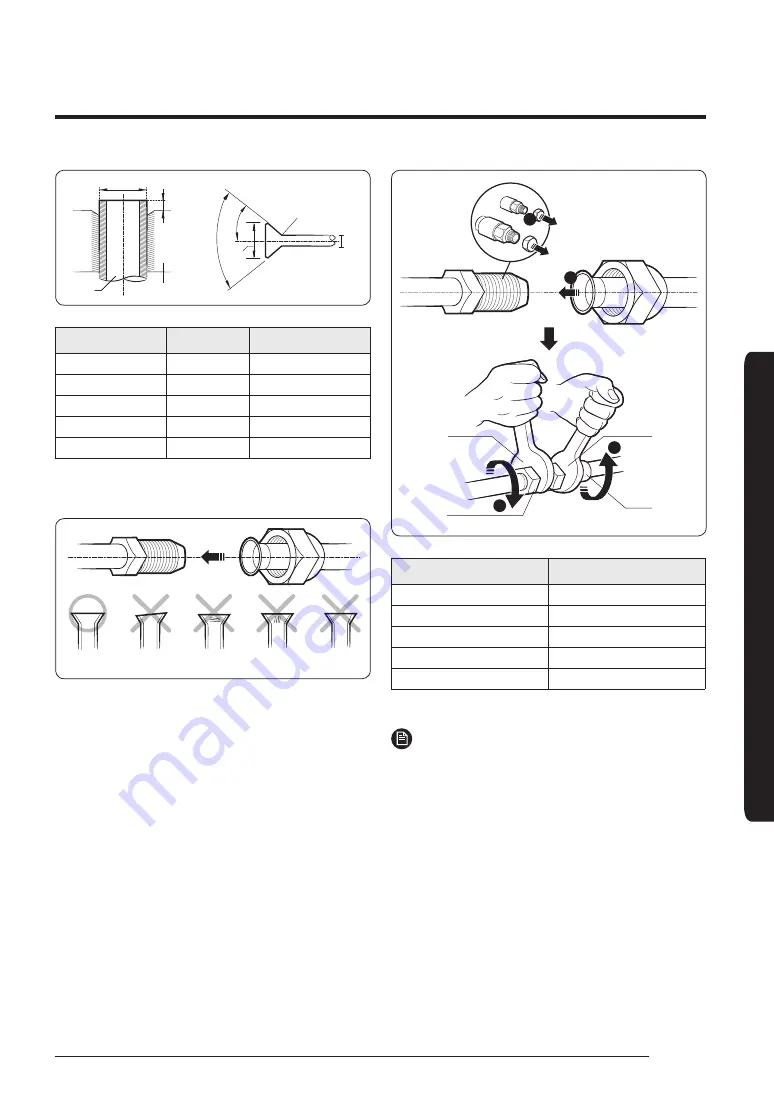

Pipe

Flare

D

A

Flare

90° ±2°

R 0.4 to 0.8 mm

D

L

45

°

±2

°

Outer Diameter (D)

Depth (A)

Flare dimension (L)

Ø6.35 mm

1.3 mm

8.7 to 9.1 mm

Ø9.52 mm

1.8 mm

12.8 to 13.2 mm

Ø12.70 mm

2.0 mm

16.2 to 16.6 mm

Ø15.88 mm

2.2 mm

19.3 to 19.7 mm

Ø19.05 mm

2.2 mm

23.6 to 24.0 mm

5

Check that the flaring is correct, referring to the

illustrations below for examples of incorrect flaring.

Correct

Inclined

Damaged

Surface

Cracked

Uneven

Thickness

Step 6 Connecting the assembly

pipes to the refrigerant pipes

There are two refrigerant pipes of different diameters :

• A smaller one for the liquid refrigerant.

• A larger one for the gas refrigerant. The inside of copper

pipe must be clean and has no dust.

1

Remove the pinch pipe on the pipes and connect the

assembly pipes to each pipe, tightening the nuts, first

manually and then with a torque wrench, a spanner

applying the following torque.

2

3

3

1

Torque

wrench

Flare nut

Spanner

Union

Outer diameter (mm)

Torque (N•m)

Ø6.35

14 to18

Ø9.52

34 to 42

Ø12.70

49 to 61

Ø15.88

68 to 82

Ø19.05

100 to 120

(1 N•m=10 kgf•cm)

NOTE

• If the pipes must be shortened, see

Step 5 Cutting and

flaring the pipes

on page

8

.

2

Be sure to use an insulator thick enough to cover the

refrigerant tube to protect the condensate water on the

outside of the pipe falling onto the floor and to improve

the efficiency of the unit.

3

Cut off any excess foam insulation.

4

Make sure that there are no cracks or waves on the bent

area.

5

It would be necessary to double the insulation thickness

(10 mm or more) to prevent condensation even on the

insulator when if the installed area is warm and humid.

Содержание AC TNCDKC Series

Страница 26: ......