36

EB 8310-5 EN

Servicing

To prevent the O-ring from being dam-

aged, use a suitable tool to slide the

O-ring onto the actuator stem and to po-

sition it correctly.

10. Screw the nut (A33) against the com-

pressor (A35). On tightening against the

glued hexagon nut (with 175 cm²) or on-

to the slotted nut (with 750 cm²), use a

suitable tool to hold it stationary. Ob-

serve tightening torques. Make sure that

the diaphragm does not turn.

11. Apply a suitable lubricant to the actuator

stem (A7).

12. Place the diaphragm plate assembly con-

sisting of the actuator stem (A7), dia-

phragm plate (A5), and diaphragm (A4)

into the bottom diaphragm case (A2).

13. Place the springs (A10) in the diaphragm

plate (A5), centering them in the intend-

ed recesses.

14. Place on the top diaphragm case (A1).

Ensure that the compressed air connec-

tions on the cases (A1, A2) are correctly

aligned with each other.

15. If necessary, preload the springs (see

section 5.2).

16. Fasten the top and bottom diaphragm

cases (A1, A2) together using the nuts

(A21) and bolts (A20). Tighten the nuts

evenly. Observe tightening torques.

17. Mount the actuator on the valve (see sec-

tion 5.1).

Version with direction of action "actuator

stem retracts" (FE)

1. Lift the actuator off the valve. See sec-

tion 9.2.

2. Unscrew the nuts (A21) and bolts (A20)

on the diaphragm case.

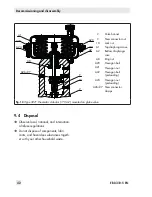

A7

A4

A36

A33

A9

A35

A5

A17

A36

A33

A7

A17

A35

A4

A5

A34

A4

Diaphragm

A5

Diaphragm plate

A7

Actuator stem

A9

Nut

A17 O-ring

A33 Nut

A34 Slotted nut

A35 Compressor

A36 Spacer

Fig. 12:

Arrangement of parts for "stem retracts" direction of action (left: 175 cm²; right: 750 cm²)

Содержание 3277

Страница 46: ...46 EB 8310 5 EN...

Страница 47: ...EB 8310 5 EN 47...