www.larius.com

6

GHIBLI 10:1

ED.

05 - 10/2020 - Cod. 150154

2

1

3

1

2

FOR CONNECTION BETWEEN PUMP, FLEXIBLE HOSE AND

SPRAY GUN BEFORE USING THE EQUIPMENT.

• ALWAYS USE THE FLExIBLE HOSE SUPPLIED WITH STAN-

DARD KIT.

• THE USE OF ANY ACCESSORIES OR TOOLING OTHER THAN

THOSE RECOMMENDED IN THIS MANUAL, MAY CAUSE

DAMAGE OR INJURE THE OPERATOR.

• THE FLUID CONTAINED IN THE FLExIBLE HOSE CAN BE VERY

DANGEROUS. HANDLE THE FLEXIBLE HOSE CAREFULLY. DO

NOT PULL THE FLEXIBLE HOSE TO MOVE THE EQUIPMENT.

NEVER USE A DAMAGED OR A REPAIRED FLEXIBLE HOSE.

The high speed of travel of the product in the hose

can create static electricity through discharges

and sparks. It is suggested to earth the equipment.

The pump is earthed through the earth cable of

the supply.

The gun is earthed through the high pressure

flexible hose.

All the conductors near the work area must be

earthed.

Avoid approaching too much to the pump piston

rod when the pump is working or under pressure.

A sudden movement of the piston rod can cause

wounds or finger squashing.

Never spray over flammable products or solvents

in closed places.

Never use the tooling in presence of potentially

explosive gas.

Always check that the product is compatible with

the materials composing the equipment (

pump,

spray gun, flexible hose and accessories

) with

which it can come into contact. Never use paints

or solvents containing Halogen Hydrocarbons

(

as the Methylene Chloride

). If these products

come into contact with aluminium parts can

provoke dangerous chemical reactions with risk

of corrosion and explosion.

If the product to be used is toxic, avoid inhalation

and contact by using protection gloves, goggles

and proper face shields.

Take proper safety measures for the protection

of hearing in case of work near the plant.

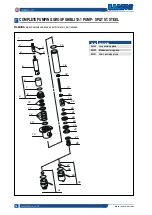

Pos.

Code

Description

1

510500

Pneumatic ram 200 lt. - single column

510000

Pneumatic ram 200 lt. - double column

2

510777

Shovel plate

3

3460

Adapter for fastening to a 200 lt drum

EXAMPLES OF USE

GHIBLI 10 :1

pump can be used in different ways according to

the model and conditions of use. Here below some examples

of the application of the

GHIBLI 10 :1

pump and of the relevant

accessories are shown.

GHIBLI 10 :1

pump long version, for transferring from 200 lt.

drums fixed on pneumatic ram or directly on drum.

GHIBLI 10 :1

pump medium version, for transferring from 60 and

30 lt. drums fixed on trolley mounted pneumatic ram.

G

Содержание Larius GHIBLI 10:1

Страница 26: ...I n t e n t i o n a l l y b l a n k p a g e...