Index revision : A

8

7021

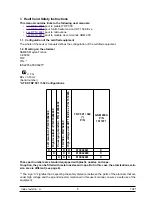

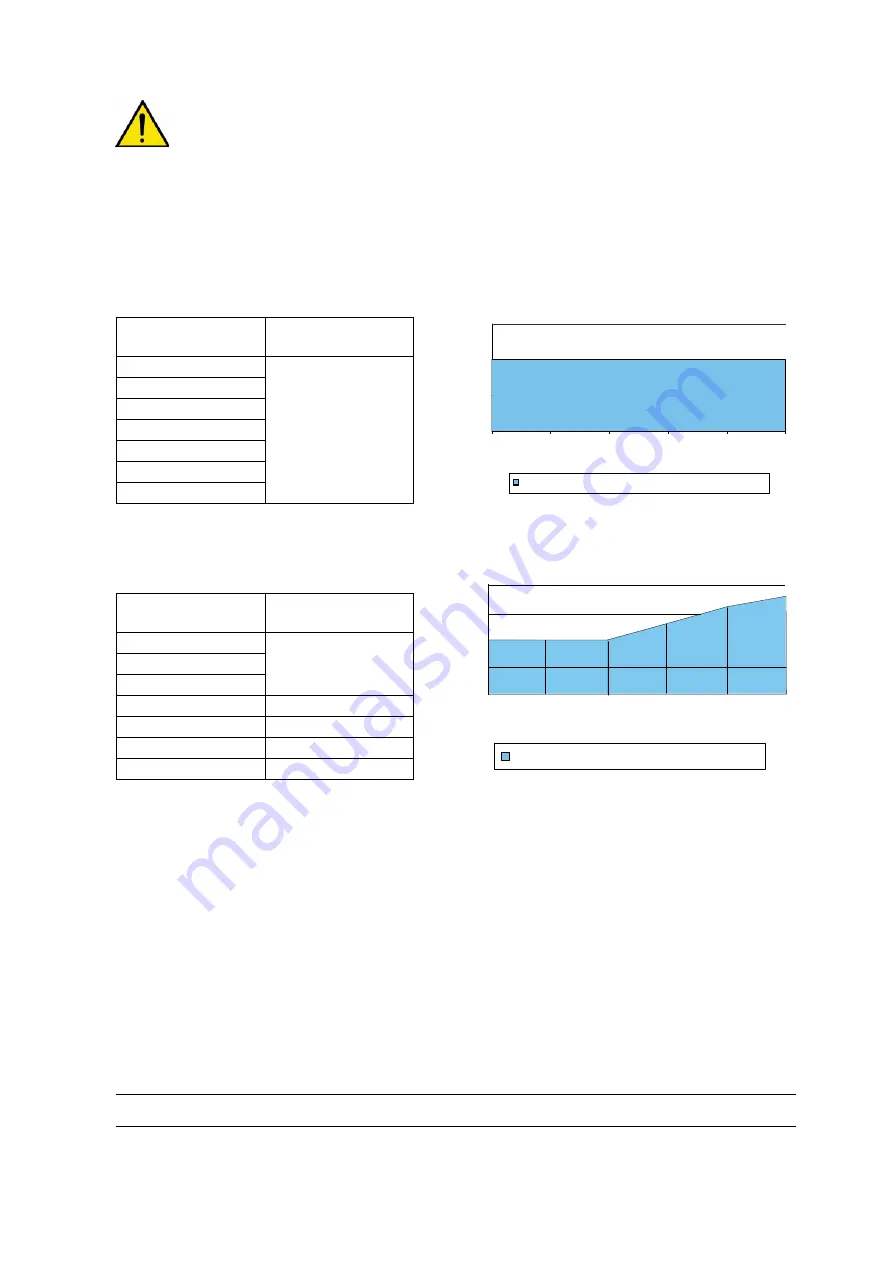

WARNING : The use of very high voltage increases the risk of sparks. SAMES Technologies

atomizers and high-voltage electrostatic generators are designed to minimize this risk. Although

the HV electrode is the only accessible part, a safety distance of X mm (refer to: Board) has to be

maintained between the parts of the sprayer that are under high voltage and all the parts that are

grounded.

TRP 501/502 with plastic nozzle and cap and UHT 156 EEx e

Authorised spraying distance

TRP 501/502 with metallic nozzle and cap and UHT 156 EEx e

Authorised spraying distance

In addition, a careful check must be made to ensure that any conducting or semi-conducting part closer

than 2.5 m to the atomizer is correctly grounded.

If it is not, electrical charges capable of causing sparks could build up on it. Operating personnel must

wear anti-static shoes and gloves to avoid this risk.

All metal parts of the booth and parts to be painted must be correctly grounded. Ground resistance must

be less than or equal to 1 M

Ω

(minimum measurement voltage 500 V). This must be checked regularly.

Grounding is mandatory for all the conductive envelops of the electrical equipments and for all the con-

ductive components within explosive atmospheres by conductive connection with the ground terminal.

Finally, for the same reasons, the spraying area must have an anti-static floor, such as concrete, metal

duckboard, etc.

It is essential to provide sufficient ventilation in the spraying booths to avoid the build up of inflammable

vapors.

Voltage

(kV)

Distance

(mm)

0

100

50

60

70

80

90

100

Voltage

(kV)

Distance

(mm)

0

100

50

60

70

130

80

160

90

180

100

200

0

50

100

150

0

50

60

70

80

90

DES03584

Distance (mm)

Tension (kV)

”X” safety distance depending on the

voltage

Unauthorised spraying zone

0

50

100

150

200

80

90

70

60

50

0

DES03585

Distance (mm)

Tension (kV)

”X” safety distance depending on the

voltage

Unauthorised spraying zone