Use of the product

31

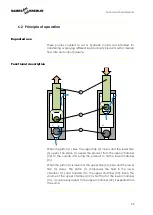

Suction Valve Pin

Adjustment

Depending on the viscosity of the medium to be pumped, position

the lower plug pin as shown below.

(For a full description of spare parts, see Part 12 - Spare Parts)

As this pump is mainly dedicated to the transfer and

application of viscous products, the pin is, when leaving

the factory, positioned at the highest point. This allows

the ball to move far away from the seat and allow the

liquid to enter the pump during suction without hindering

its passage.

Lower Hole

position

High Hole

position

Ball

Ball

Seat

Seat

Mounting for

"Fluid" product

Assembly for

"Medium

Viscosity"

product

Spacer

Spacer