Operator's manual

Tractor sweeper

MOP

- 18 -

Fig. 19

Fig. 20

Fig. 21

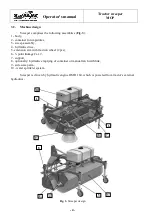

1)

Unscrew bolts M10x30 on container frame feet set (it.

20) and insert bolts with heads up in the bracket

channel on the sweeper's body (Fig. 19). Adjust the

container frame set on the bolts, pre-tighten all nuts

(pay attention to washers). Check whether the frame

feet are evenly set on the sweeper's body, and then

tighten nuts.

2)

Tighten the sprayer bar (it. 4) with bolts M8x25 to the

bracket I and II of the right and left mounting of the

container (Fig. 20).

3)

Before sliding over flexible hose III (it. 7) onto sprayer

nozzle (it. 16) installed on the bar, place hose clamp,

and then slide the hose onto the ending. Secure the hose

from being retracted by tightening the clamp on the

coupling - use the screwdriver (Fig. 21).

4)

For installing the set on the sweeper with the side brush,

marginal mounting set (it. 17) should be installed. The

mounting is to be tightened on the side brush shield

(Fig. 22) in round assembly mounting (it. 18). Use

industrial rubber belt (it. 10) delivered to remove any

plays on the mounting by tightening bolt M6x25 to set

the spraying angle to 45

°

to the ground.

Prior to operation commencement:

Inspect, and if need be, re-tighten bolts and nuts,

Examine connections on the flexible hose,

Fill the water tank and connect the water pump power supply to 7 PIN socket, being the

tractor's equipment. Start the pump, check whether there are no leaks in the system and the

nozzles work properly.

Fig. 22