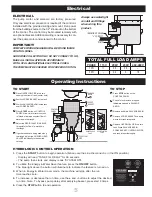

Operating Instructions

GUSHER HEAD

VALVE

RECIRCULATION

VALVE

3

B

C

SALVAGE

BASIN

CONTROL

PANEL

4 A

2

D

SCRAP

BASKET

1

E

OVERFLOW

PIPE

6

5

TO START

l

1

Place OVERFLOW PIPE into drain

opening in bottom of tank (center hole).

l

2

Position SCRAP BASKET inside tank.

l

3

Position SALVAGE BASIN inside tank

over SCRAP BASKET.

l

4

Press START button on CONTROL

PANEL. Allow time for reservoir tank

to fill and maintain a constant flow of

water down the trough.

l

5

Adjust the RECIRCULATION VALVE

to regulate the flow of water down

the trough.

l

6

If gusher heads are being used along

the trough, adjust the GUSHER HEAD

VALVES individually to the desired

settings.

TO STOP

l

A

Press STOP button on the

CONTROL PANEL.

l

B

Check for and remove dropped

tableware trapped in SALVAGE

BASIN.

l

C

Remove and drain SALVAGE BASIN.

l

D

Remove SCRAP BASKET and dump

waste into trash receptacle.

l

E

Remove OVERFLOW PIPE to drain

tank.

Rinse SALVAGE BASIN,

SCRAP BASKET, OVERFLOW PIPE,

and tank interior thoroughly.

HYDROLOGIC CONTROL OPERATION

1. Press the START button to begin operation. (Make sure the Line Disconnect is in the ON position)

• Display will read “TANK FILL DELAY” for 30 seconds.

• The pump then starts and display reads “SYSTEM ON”.

2. To utilize the Energy & Water Saver feature, press the ON/OFF button.

The blue light above the button will illuminate to indicate the feature is turned on.

3. When in Energy & Water Saver mode, the machine will stop after the run

time reaches zero.

4. To increase or decrease the run time, use the + and - buttons to adjust the desired

run time. Note: To bypass pump delay after emptying basket, press start 2 times.

5. Press the STOP button to end operation.

5

Electrical

INCOMING POWER

1

/

2

" CONDUIT

PUMP

ELECTRICAL

The pump motor and solenoid are factory pre-wired.

Only one electrical connection is required if the control is

installed with the provided wiring and mount. Run power

from the building source to the 1/2” knockout on the bottom

of the control. The control may be mounted remotely with

an optional bracket. Additional wiring is necessary to con-

nect the pump motor and solenoid to the control.

IMPORTANT!

COMPLETE WIRING DIAGRAMS WILL BE FOUND INSIDE

CONTROL PANEL.

HARD WIRE COLLECTOR ONLY. DO NOT CONNECT TO GFI.

MAKE ALL INSTALLATIONS IN ACCORDANCE

WITH LOCAL AND NATIONAL ELECTRICAL CODES.

THE PUMP MUST BE CHECKED FOR PROPER ROTATION.

Always use watertight

conduit and fittings

when wiring this

product.

PHASE 115V 208V 230V 460-480V

1 PH

11

5.5

5.5

–

3

PH – 3.2 3 1.5

TOTAL FULL LOAD AMPS