DIF.P - DIF.A

SIEF_20200507_DIF.P-DIF.A _M

10

Terminali filtranti per ambienti a contaminazione controllata

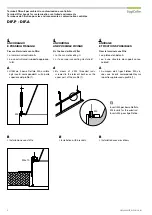

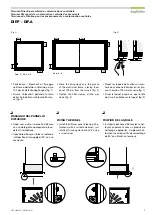

OBIETTIVO

Verifica della tenuta del sistema filtro più

cassonetto. Questo test di validazione

deve essere eseguito da personale qua-

lificato.

OPERAZIONI PRELIMINARI

1. Installare il filtro come indicato nel

punto 5;

2. Archiviare il certificato individuale che

deve essere conservato;

3. Dopo accurata pulizia della stanza,

eseguire il primo avvio dell’impianto

tenendolo in funzione fino al raggiun-

gimento e mantenimento della classe

di pulizia richiesta in accordo alla ISO

14644-4.

ACCORGIMENTI DURANTE IL TEST

1. Verificare che il fotometro in uso ab-

bia uno ZERO stabile, per evitare false

letture;

2. Nel caso di rilevamento di una perdita,

in prossimità del perimetro del siste-

ma, separare la zona in test e l’am-

biente esterno con cortine e verificare

se le letture non dipendano da effetti

di induzione (vortici perimetrali, effetto

Venturi).

8

LEAK-TEST

Terminal filter hoods for contamination controlled environments

SCOPE

Check for leaks in the filter system and

cabinet. This validation test must be per-

formed by qualified personnel.

GETTING STARTED

1. Install the filter as shown in point 5;

2. File away the individual certificate

which should be kept;

3. After thorough cleaning of the room,

switch on the ventilation system until

the required class of cleanliness, ac-

cording to ISO 14644-4 has been rea-

ched and maintained.

TIPS DURING THE TEST

1. Make sure the photometer in use has

a stable ZERO to avoid false readings;

2. If a leak is detected near the perimeter

of the system, separate the area being

tested from the external environment

using screens and check whether the

readings do not depend on induction

effects (perimeter vortexes, Venturi ef-

fect).

8

LEAK-TEST

Terminaux de filtration pour les environnements à contamination contrôlée

OBJECTIF

Vérification de l’étancheité du système de

filtre et du caisson. Ce test de validation

doit être effectué par un personnel qua-

lifié.

OPÉRATIONS PRÉALABLES

1. Installer le filtre comme indiqué au

point 5 ;

2. Archiver le certificat individuel qui doit

être conservé ;

3. Après un nettoyage soigné de la salle,

effectuer une première mise en route

de l’installation jusqu’à obtention et

maintient de la classe ISO recherchée

en accord avec l’ISO 14644-4.

MESURES À PRENDRE PENDANT

LE TEST

1. Vérifier que le photomètre utilisé ait un

ZÉRO stable, pour éviter de fausses

lectures ;

2. En cas de détection de fuite, à proxi-

mité du périmètre du système, sépa-

rer la zone testée et l’environnement

extérieur à l’aide de rideaux et vérifier

si les lectures ne dépendent pas d’ef-

fets d’induction (tourbillons périmétri-

ques, effet Venturi).

8

LEAK-TEST