16

XL-TG10153BM-en-US Rev A · 2013-06-27 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

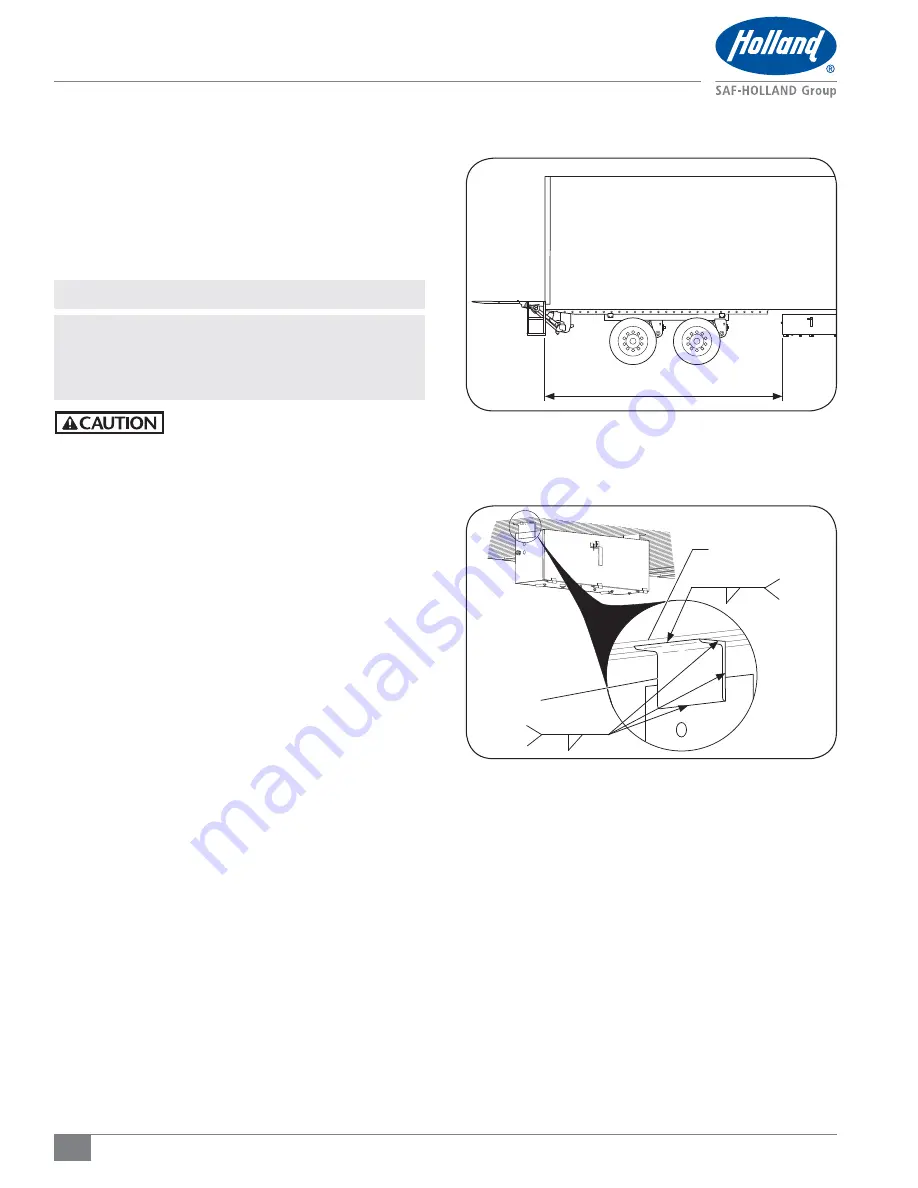

Pump Assembly Installation

Figure 25

Figure 24

Side Mount and Battery Box

1. Locate the pump box assembly on the curbside under the

vehicle on front of the sliding suspension but no more

than 20' (6096 mm) from the back of the vehicle and 6"

(152 mm) from the curbside of the vehicle body

(Figure 24).

2. Position the pump assembly brackets against the

trailer crossmembers.

IMPORTANT:

Ensure the lid can be removed.

NOTE:

When welding is required, ensure that the battery

ground cable is disconnected and that all electrical

equipment is completely electrically isolated

before welding is initiated.

Failure to isolate electrical equipment

from ground prior to welding could result

in overload which, if not avoided, could

result in property damage.

3. After the main tube is positioned correctly, prep the vehicle

frame. With a grinder, remove any paint or galvanizing

within 1" to 4" (25-101 mm) of the weld surface.

4. Weld the pump and battery box to the vehicle

crossmembers

(Figure 25).

5. Touch up paint as required. For galvanizing liftgates,

touch up in accordance with the most recent release of

ASTM A 780: Standard Practice for Repair of Damaged

and Uncoated Areas of Hot Dip Galvanized Coatings,

which specifies the use of zinc-rich paints.

1/4"

20' (6096 mm)

1/4"

TYP

TYP

PUMP BOX

MOUNTING

BRACKET

CROSSMEMBER