6

SPECIFICATIONS

Oscillating Range

5/8 in. (15.9 mm)

Oscillations Per Minute

58 OPM

Spindle Size

1/2 in. (12.7 mm)

No Load Speed

2000 RPM

Input

120 Volts, 60 Hz, AC only, 3.5 Amps

Weight

49 lbs. (22.2 kg)

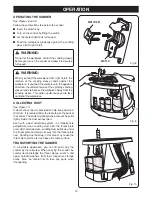

UNPACKING

INFORMATION

We have shipped the oscillating spindle sander

completely assembled and ready to use with a 1 in.

(25.4 mm) rubber spindle, 7/8 in. (22.2 mm) upper

spindle washer, 1 in. (26 mm) throat plate, and 80 grit

1 in. (25.4 mm) sanding sleeve installed on the spindle.

■

Remove the loose parts from the box. Make sure

that all items listed in the loose parts list are in-

cluded.

■

Remove the packing materials from around the tool.

■

Lift the tool carefully from the box and place it on a

level work surface.

NOTE:

The sander is heavy. Ask for assistance if

necessary.

■

Do not discard the packing material until you have

carefully inspected the tool, identified all loose parts,

and satisfactorily operated the tool.

■

If any parts are damaged or missing, please call

1-800-525-2579 for assistance.

■

Inspect all parts carefully to make sure no breakage

or damage occurred during shipping.

WARNING:

If any parts are missing do not operate the tool until

the missing parts are replaced. Failure to do so

could result in serious personal injury.

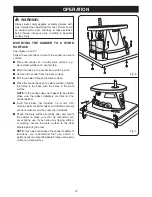

LOOSE PARTS LIST

1. Sanding sleeves, 50, 80, 150 grit (17)

2. Rubber spindles (4)

3. Throat plates (5)

4. Upper spindle washers (2)

5. Wrench

1

2

3

4

5

Содержание OSS500

Страница 15: ...15 NOTES...