61

ITEM

PART NO.

DESCRIPTION

QTY

ITEM

PART NO.

DESCRIPTION

QTY

HEAVY DUTY

SOD CUTTER

1

64006-06

LOCKWSHR-HELICAL 7/16 2

2

304364

NUT-HEX 7/16-14

2

3

64001-6

NUT-HEX JAM, 3/8-16

2

4

64006-03

LOCKWASHER, 3/8

2

5

64123-75

BOLT, 3/8-16X3 HEX

2

6

311397

SCRW,.44-14 3.00 YS HX G5 2

7

316942

PIN,SPIROL.250.500 PS

2

8 515759 BUSHING

2

9

515888

WASHER,.62.88.15 NS FLAT 2

10 515958

PLUNGER

2

11 520605

WASHER-THRUST

2

12 520606

PIVOT-CENTER

1

13 520617

STRIP-BUSHING

1

14

823269

WASHER, 7/16

2

15 524809.7 SCRAPER-WHEEL

2

16 64163-67 WASHER-.516X1X12GA 2

17 546153

BARREL-WHEEL

2

18 547403

ARM-WHEEL

2

19 547404

AXLE

1

20 4124197 WHEEL-REAR

2

*523261

TUBE

1

*523262

TIRE

1

*523263

BEARING

1

21

547414

YOKE, COMPLETE

2

(INCLUDES ITEM 22)

22 516915

BUSHING

2

23

64151-7

NUT-HEX 1/2-13 CTRLCK

2

24

64229-03

NUT-NYLON LOCK 3/8-16

2

25

548206

SET SCREW, 3/8-16x1-1/2

2

26

85010N

ZERK-1/4-28 STR S-TAP

1

27

64123-135

BLT-HEX 1/2-13X5

2

28

523053

SPACER,.51 .75 3.28 ZS

2

29

35027N

FITTING-ZERK 90DEG.

2

30 816449

WASHER

2

* NOT ILLUSTRATED

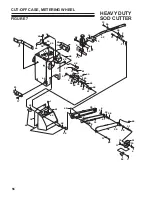

REAR WHEELS

FIGURE 9

Содержание 544853G

Страница 2: ......

Страница 45: ...HEAVY DUTY SOD CUTTER 43 PARTS SECTION...