20

COMPILER TECO/ATI

ENDORSED

DATE

29.02.2004

REG. CODE

1-5302-633

MODEL N°

51074

DATE OF ISSUE

02-04

REVISION

00

X

12

13

14

15

42.3 ÷ 43.7

28.3 ÷ 28,5

18,7 ÷ 18,9

14,91

±5%

Kg

D

C

A

2

°

1

°

3

°

B

X

90° - 120°

Ra = 0,5 - 1 µ

24,72

±5%

Kg

Ø 87 ÷ 87,020

CHECKS AND OVERHAUL

Free length

Grinding-in must always be carried out when new valves or

housings are mounted. Valve housings oversized on the outside by

0.5 mm are available.

Thoroughly wash the valve and housing with petroleum or gasoline

to eliminate lapping paste residues or swarf.

Proceed in the following way to make sure that the valve and seat

are tight:

1. Mount the valve on the head with cap string and cotters (see fig.

8)

2. Overturn the head and pour a few drops of diesel fuel or oil on

to the edge of the valve top

3. Blow compressed air into the head duct. Plug the edges of the

duct itself to prevent air escaping.

If there are air leaks in the form of bubbles between the housing

and valve, demount the valve and grind-in again.

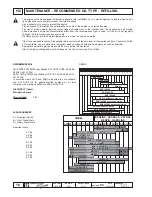

Valve springs

Check the length of the spring as indicated in fig. 13 to identify any

yielding.

Replace the springs if the values are different.

Rocker arms

Make sure that there are no evident signs of wear on the contacting

surfaces. Replace the parts if necessary.

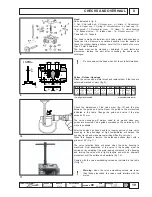

Cylinder

In special cast iron with integral liner. Use a bore gauge to check

the two internal diameters

(C-D)

perpendicular to each other and at

different heights (fig. 14). Maximum tolerated taper error

(A-B)

and

ovality error

(C-D)

: 0.06 mm.

Cylinder diameter:

If the diameter of the cylinder does not exceed said values or if there

are slight surface scores on the cylinder, it will be sufficient to

change the piston rings.

Do not manually hone the cylinder bore surfaces with

emery cloth or other means.

The cross-hatch pattern should be at an angle of 90°÷120°; lines

should be uniform and clear in both directions (fig. 15).

Average roughness must range between 0.5 mm 1 µm.

The cylinder surface which comes into contact with piston rings

should be machined with the plateau method.

Replace the cylinder and piston if there is a ridge in zone "

X

" fig. 15

of the cylinder and if tapering and ovality exceed the previously given

values.