DESCRIPTION

The Royal Cheltenham glass fronted high efficiency live fuel effect inset gas fire has been developed from the

successful Royal Cozyfires.

The fuel bed has a realistic coal effect utilising ceramic ‘coals’ and coal bed that allows secondary air to be entrained

into the bed for clean combustion, the burner is an aerated twin ported steel burner running parallel across the front

of the fire. A gas control with a variable high to low setting with a separate piezo igniter is used to ignite a Oxy-

pilot device to prevent continued spillage occurring under hazardous flue conditions with the protection of a flame

supervision device.

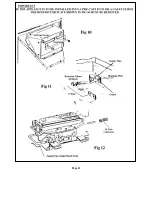

The fire is suitable for use in conjunction with 228mm x 228mm (9" x 9")(Class 1) flues, 125mm (5") diameter twin

walled metal flues (Class 2) and properly constructed pre-cast flues to BS 1289 PT1 1986 & 1975. A spacer frame

is supplied to assist with the installation into pre-cast flues or where a reduced depth is available.

The installation must always be used in conjunction with a suitable hearth and surround (refer to fig 1 for further

details).

IMPORTANT NOTES

Areas of this appliance will become hot after prolonged running and it is recommended that for the protection of the

very young, elderly and infirm a fireguard conforming to BS 6539 or BS 6778 be used.

Additional purpose built ventilation is not required for this appliance in GB only, for IE ventilation is required with

a minimum cross sectional area of 100 sq. cms and should be checked regularly to ensure that it is free from

obstruction.

Care should be taken to prevent any damage being caused to surrounding soft furnishings or decor e.g. many

embossed vinyl wall coverings may become discoloured if located too close to the appliance. Clearances required

for combustible shelves are shown on page 4.

This product uses fuel effect pieces, gaskets and insulation material containing Refractory Ceramic Fibre (RCF),

which are man-made vitreous silicate fibres. Excessive exposure to these materials may cause temporary

irritation to eyes, skin and respiratory tract, consequently, it makes sense to take care when handling these

articles to ensure that the release of dust is kept to a minimum.

A hearth must always be provided to project forwards of the back panel a minimum of 300mm and a minimum of

150mm either side of the fire opening. The hearth must be a minimum thickness of 12mm with a perimeter height

of 50mm, to discourage placing carpets or combustible materials close to the fire.

The area under the appliance must have a minimum non-combustible thickness of 25mm. In most installations a

back panel will be required, this must be either non-combustible or have a minimum fire resistance rating of Class

O (100

o

C).

The glass front is manufactured from three separate panels, when the appliance is cold a small gap may appear

between the joints, this is normal and does not impede the function of the appliance. The brass trims are covered

with a protective polycoat that must be removed prior to lighting the appliance.

TECHNICAL DATA

Overall height of fire

= 620mm

Type of gas

Natural Gas only (G20)

Overall width

= 660mm

Setting pressure /- 1mbar (cold)

Overall depth

(Forward of plane of opening)

= 180mm

Heat Inputs

Max

5.42kW

(18500 Btu/h)

Overall depth with spacer

(Forward of plane of opening)

= 230mm

Min

2.34kW

(8000 Btu/h)

Minimum height of opening see fig 1 = 560mm

Pilot

0.26kW

(890 Btu/h)

Minimum width of opening see fig 1 = 400mm

Main Injector types

Bray

82/380

Minimum depth of opening see fig 1 = 220mm

Stereomatic

Size 68

Minimum depth with spacer

= 17Omm

Pilot Assembly

E.A.S.D Oxypilot NG 9O22

Gas Connector8mm O/D Tube

Weight

26.7Kgs

Page 2

Содержание U19019 G20

Страница 12: ...Page 5 ...

Страница 16: ...Page 8 ...

Страница 17: ...Page 9 ...

Страница 18: ...Page 10 ...

Страница 19: ...Page 11 ...

Страница 20: ...Page 12 ...

Страница 23: ...Page 15 ...