Introduction/Safety/Installation 7

SG80AII

Manual

www.rottlermfg.com

Emergency Procedure:

Assuming one of the following has occurred: tool bit set completely off size, work piece or spindle base

not clamped, spindle is not properly centered, and these mistakes will become obvious the minute the cut

starts

PRESS THE EMERGENCY STOP BUTTON (on the front control panel) IMMEDIATELY!

Find out what the problem is; return the spindle to its up position without causing more damage. To

restart the machine, turn the Emergency Stop Button CW until the button pops out. Make sure the button

has been depress for at least 1 ½ minutes or the drive will not have time to reset and they will not

function.

Be alert to quickly stop the machine in the event of a serious disruption of the boring process either at the

top or bottom of the bores.

“REMEMBER”

metal cutting tools have the speed and torque to severely injure any part of the human

body exposed to them.

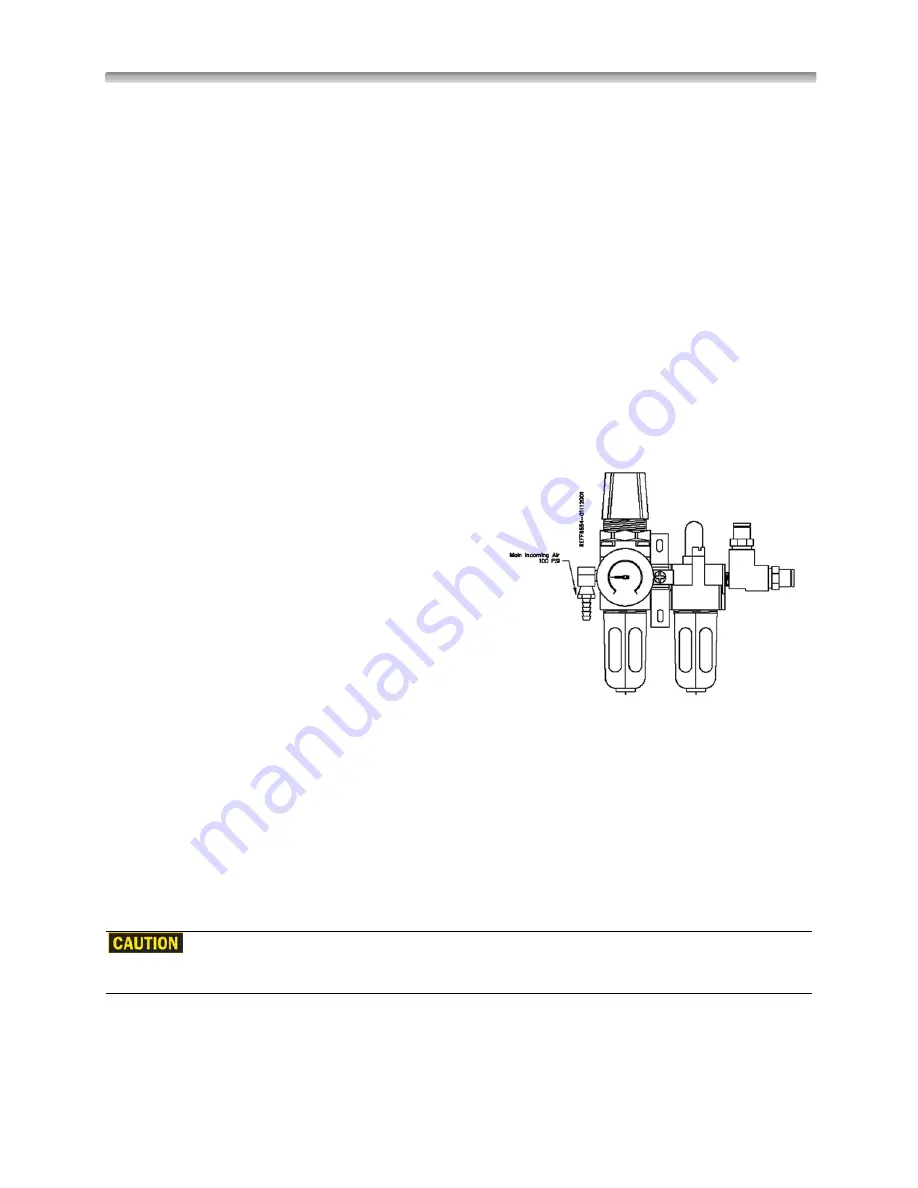

Air Supply:

It is very important the air source for the SG80AII

machine be moisture free. Water and oil in the line will

result in early cylinder and valve failure. The factory

recommends installing a water trap at the machine.

Attach a 100 P.S.I. air source to the appropriate intake

in the small enclosure located on the left rear of the

machine near the bottom.

Bellow you will se the Air regulator panel for the

different settings on the flouting planes on the machine.

And cabinet cooler air regulator.

Air Adjustments

:

Float:

The float regulator is located at the rear of the spindle base on the bottom of the interconnect box.

If the machine is not floating properly, it could be from too much or too little air from the regulator. Turn

the regulator all the way off (full counter clockwise).

Start turning the regulator slowly clockwise while continually checking the Work Head for proper

floatation. Once the correct float is established, lock the regulator into place by pushing in on the blue

adjusting knob.

:

Use as little air as possible to achieve correct floatation. Using too much air will could cause

the spindle base to move slightly to the right when going into tilt. This will cause a scratch up the side of

the cylinder.

Содержание SG80AII

Страница 2: ......

Страница 12: ...Introduction Safety Installation 9 SG80AII Manual www rottlermfg com Electrical Enclosure ...

Страница 15: ...Introduction Safety Installation 12 SG80AII Manual www rottlermfg com Location of the Shipping Brackets ...

Страница 49: ...Machine Parts 7 SG80AII Manual Type text www rottlermfg com Type text Base Assembly ...

Страница 52: ...Machine Parts 10 SG80AII Manual Type text www rottlermfg com Type text Spindle Assembly ...

Страница 56: ...Machine Parts 14 SG80AII Manual Type text www rottlermfg com Type text Transmission Assembly ...

Страница 59: ...Machine Parts 17 SG80AII Manual Type text www rottlermfg com Type text Head Support Assembly ...

Страница 66: ...Options 1 SG80AII Manual www rottlermfg com Options Options and Tooling are in separate manuals ...