-11-

Characterization

– This option provides for a 2 to 11 point

calibration of the unit in order to characterize its output. This

calibration is performed under the VALVE POS menu via the

following steps:

1. Update the MAX POSITION parameter to reflect the

value of the maximum output position of the actuator.

(ex. 100 %)

2. Select the CAL POINT 1 parameter. Use the

↑

/

↓

knob

to run the actuator to the desired ZERO position. Select

E

nter to save the current physical position of actuator as

its ZERO point.

3. Continue to the CAL PT 1 VAL parameter and select it for

update. This is the numeric value that is to be associated

with the ZERO point (ex 0 %). Update and select

E

nter to

save this value

4. Continue to the CAL POINT 2 parameter. Use the

↑

/

↓

knob to run the actuator to the desired position. Select

E

nter to save the current physical position of actuator as

the second calibration point.

5. Continue to the CAL PT 2 VAL parameter and select it for

update. This is the numeric value that is associated with

the second calibration point (ex 10 %).

6. Continue to the CAL POINT 3 parameter. Use the

↑

/

↓

knob to run the actuator to the desired position. Select

E

nter to save the current physical position of actuator as

the third calibration point.

7. Continue to the CAL PT 3 VAL parameter and select it for

update. This is the numeric value that is associated with

the third calibration point (ex 20 %).

8. Calibration points (up to 11) will be automatically

available until the CAL PT X VAL parameter is set equal to

the MAX POSITION parameter value set in step 1. When

this occurs, calibration is considered complete; no

additional calibration points are provided.

ACTUATOR SETUP

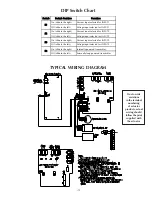

5) Transmitter

The unit may be configured to use either an internally

powered transmitter (S4 slid to the right, in line with the

painted line) or as externally loop powered (S4 slid to the

left, not in line with the painted line) The transmitter is

factory calibrated. User calibration is not required.

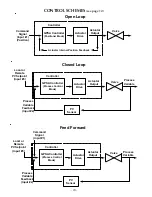

6) Loss of Command Action

The unit may be configured to perform one of four actions

when a loss of the command input signal occurs while

running under the automatic operation of the Open Loop

control mode:

LOCK – Locks the unit in place at its current position

DRIVE to ZERO - The unit will drive to the ZERO position

set in calibration

DRIVE to SPAN - The unit will drive to the SPAN position set

in calibration

DRIVE to POS - The unit will drive to a user position

specified by the CMD LOS POS parameter

7) Loss of Process Variable Input Action

The unit may be configured to perform one of four actions

when a loss of the process variable input signal occurs under

the automatic operation of the Closed Loop control mode:

LOCK - Lock the unit in place at its current position

DRIVE to ZERO - The unit will drive to the ZERO position

set in calibration

DRIVE to SPAN - The unit will drive to the SPAN position set

in calibration

DRIVE to POS - The unit will drive to a user position

specified by the PV LOS POS parameter