Maintenance

Lubrication Instructions

Motor Gear Case: It is lubricated permanently and

requires no periodic lubrication. The lubrication oil

used in the motor gear case is SAE 90.

Roller Gear Case: It is packed with grease and sealed,

and requires no periodic lubrication. If service is

required, replenish lubricant with Moly-Shield ST-200

or equivalent.

Hinge Bar: Directly above the hinge bar located on

the head casting are two 1/8" lubricating holes. Fill

holes with lubricating oil (SAE 30) every 8 hours of

operation.

Pinion Gear: On the outside of the head casting directly

opposite the pinion gear are two 1/8" lubricating

holes for the oiling of the pinion gear shaft. Lubricate

every 8 hours of operation with lubricating oil (SAE

30).

Motor: Requires no lubrication. All ball bearings are

sealed.

Cutter Wheel Alignment

Your E-Z Cutter wheel is aligned professionally by our

factory assemblymen prior to its shipping. If for some

reason your E-Z Cutter becomes out of alignment, you

will observe that the wheel is not cutting but making

thread marks on your stock.

To align the E-Z Cutter, loosen the appropriate head

aligning set screws and adjust the head to the right or

left as required. Tighten the set screws once the wheel

is aligned.

Motor Brushes

Check motor for brush wear every six months. If

motor lacks power due to a dirty commutator, use a

commutator cleaner stick or fine emery cloth.

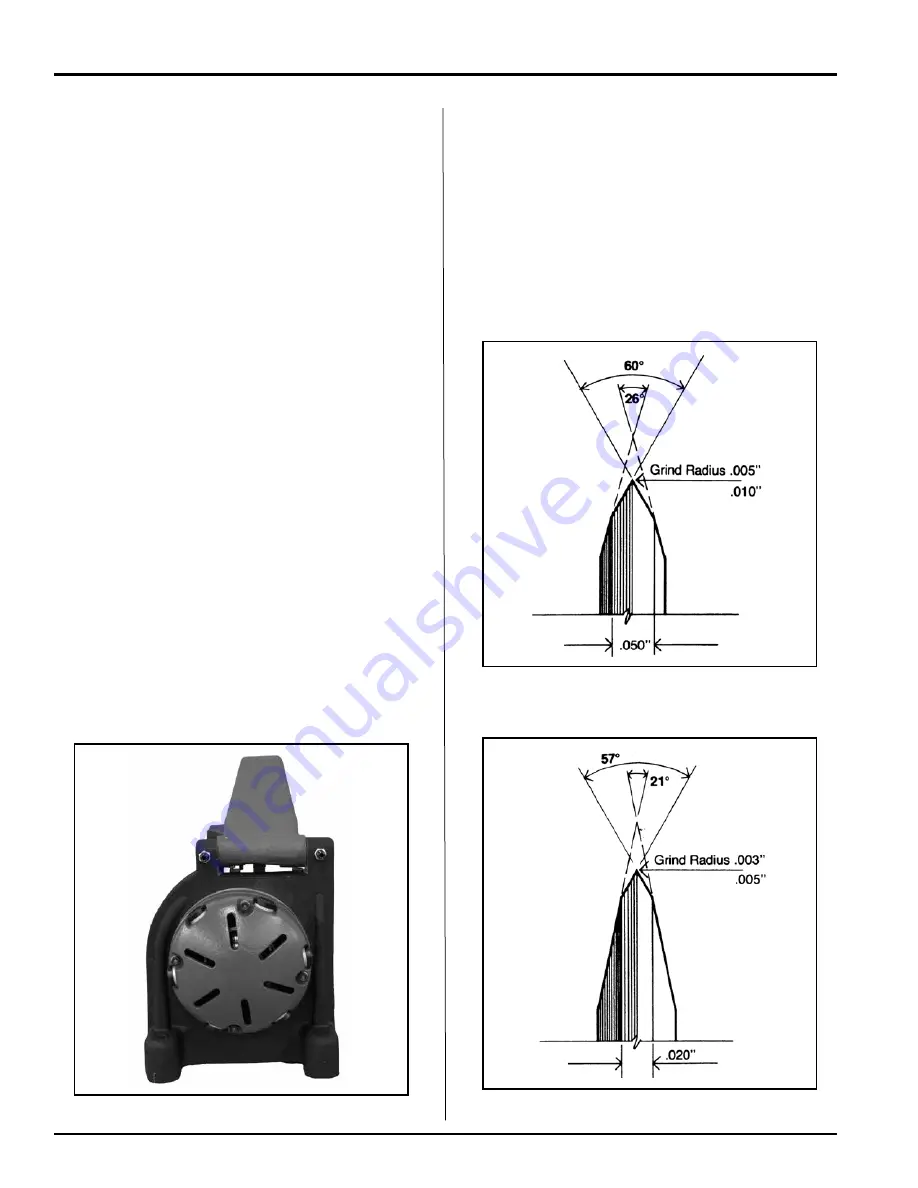

Cutter Wheel Sharpening

If you have resharpening capability locally, the follow-

ing drawings are provided for your convenience.

E-Z Cutter as seen from rear

Tube Cutter Wheel #00035

Pipe Cutter Wheel #00034

10

COLLINS E-Z CUTTER

Phone 800-545-7698 • FAX 815-633-0879

www.rothenberger-usa.com