Element 50 Manual

Original Instructions

Aug 2016

6

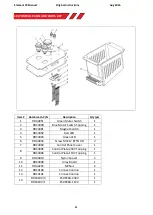

4) SPECIFICATION

Maximum hole cutting capacity in .2/.3C steel = 50mm dia. x 50mm deep

Arbor bore = MT2

Motor Unit

Voltages

110V 50-60Hz

230V 50-60Hz

Normal full load

14.9 A

1500W

6.9 A

1500W

Electro Magnet

0.53 A

56W

0.28 A

61W

Size

200mm long

98mm wide

Holding Force at 20°C with 25mm minimum plate thickness

The use on any material less than 25mm thick will progressively

reduce the magnetic performance. If possible, substitute

material should be positioned under the magnet and work

piece to equate to a suitable material thickness. If this is not

possible, an alternative secure method of restraining the

machine must be used.

13500N

Total Load ( motor)

1556W

1561W

Overall Dimensions

Height - maximum extended

586mm

Height - minimum

446mm

Width (including capstan fitting)

195mm

Length Overall (including guard)

315mm

Nett Weight

15.5kgs

15.2kgs

Element 50/1T

Element 50/3T

Vibration total values (triax vector sum) in accordance with

EN61029-1:

Vibration emission value

(a

h

):3.562m/s

2

Uncertainty(K):1.5m/s²

Vibration emission value

(a

h

):3.527 m/s²

Uncertainty(K):1.5m/s²

Level of sound pressure in accordance with EN61029-1:

Sound pressure(LpA)

:

87.0 dB(A)

Acoustic power(LwA)

:

100.0 dB(A)

Uncertainty(K)

:

3dB(A

)

Sound pressure(LpA)

:

86.0 dB(A)

Acoustic power(LwA)

:

99.0 dB(A)

Uncertainty(K)

:

3dB(A)

Ear and eye defenders must be worn when operating this machine. Wear gloves to protect hands when operating the

machine.

The declared vibration total value has been measured in accordance with a standard test method and may be used for

comparing one tool with another.

The declared vibration total value may also be used in a preliminary assessment of exposure.

The vibration emission during actual use of the power tool can differ from the declared total value depending on the

ways in which the tool is used;

The need to identify safety measures to protect the operator that are based on an estimation of exposure in the

actual conditions of use (taking account of all parts of the operating cycle such as the time and when the tool is

switched off and when it is running idle in addition to the trigger time).

These tools are UK designed and manufactured with globally sourced components and conform with the requirements

of EEC Document HD.400.1 and BS.2769/84.

Suitable only for a single phase 50-60Hz A.C. power supply

DO NOT USE ON D.C. SUPPLY

Do not use your magnetic drill on the same structure when arc welding is in progress.

D.C. current will earth back through the magnet and cause irreparable damage.

WARNING: THIS APPLIANCE MUST BE EARTHED!

NB: ANY MODIFICATIONS TO THIS MACHINE WILL INVALIDATE THE GUARANTEE