- 7 -

PRE-START CHECKLIST

(continued)

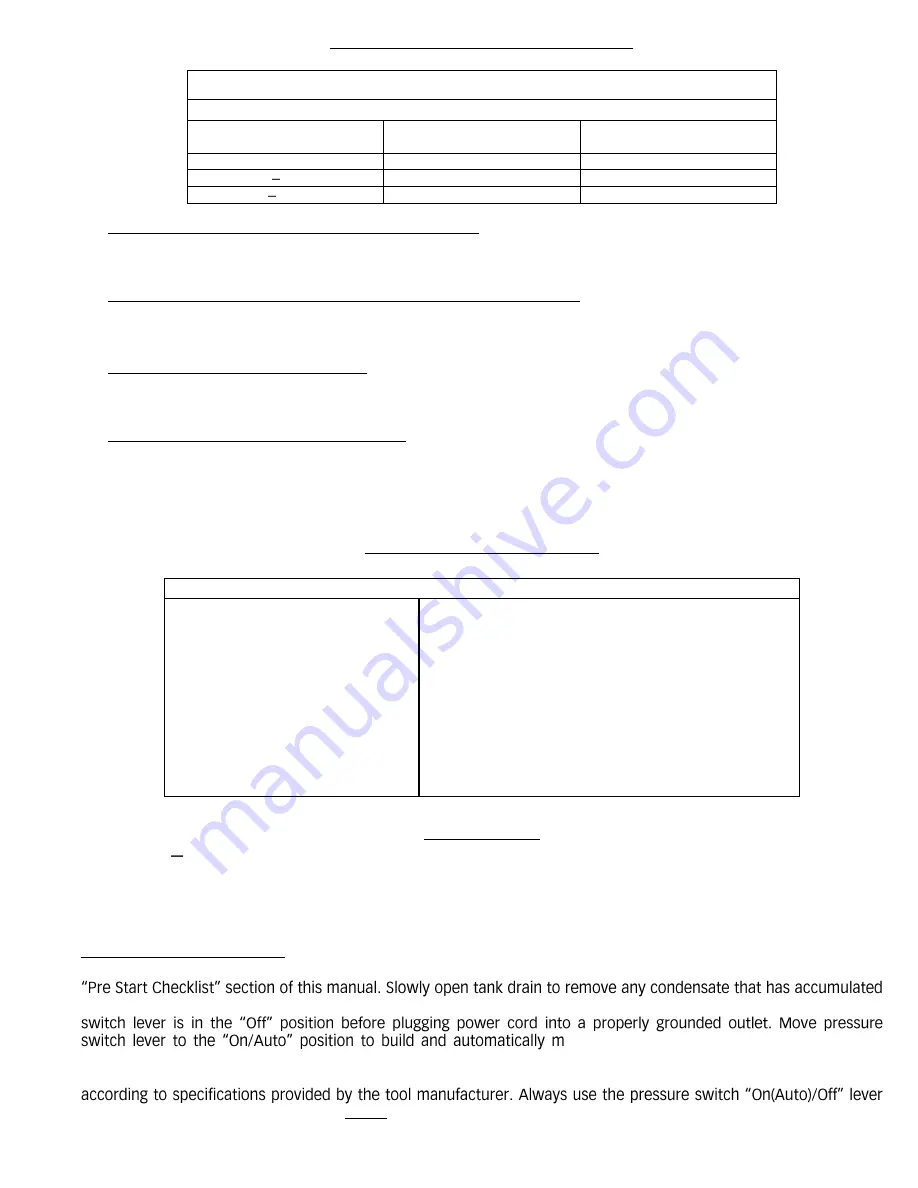

ELECTRIC EXTENSION CORD TABLE

Minimum Wire Size

Extension

Cord Length

Motor

1/2 and 3/4 HP

Motor

1, 1-1/2, and 2 HP

Up to 25 ft.

14 Ga.

12 Ga.

25 50 ft.

12 Ga.

10 Ga.

50 100 ft.

10 Ga.

8 Ga.

6.

DO NOT USE A GENERATOR AS THE POWER SOURCE

Air compressors use inductive motors that require 3-5 times the full-load amp draw to properly start. Most

generators will not provide the wattage needed to properly start this type of electric motor.

7.

CHECK TENSION OF BOLTS AND HARDWARE ON A REGULAR BASIS

Operation of any equipment with loose bolts and/or fittings will lead to excessive vibration

and the premature failure of the compressor system control components.

8.

MAINTAIN RUBBER VIBRATION PADS

Excessive vibration is a major cause of premature compressor failure. Always maintain the rubber vibration pads

located beneath tank assembly. Operation without them will void your warranty.

9.

DRAIN MOISTURE FROM AIR TANKS DAILY

Water is a natural byproduct of compressed air. Drain air tank(s) after each use to combat internal tank corrosion.

Keep drain valve(s) closed if storing compressor for any length of time.

SPECIFICATIONS

OPERATION

WARNING

Your safety and the wellbeing of others during the operation of every

ROLAIR

compressor is our main

concern. Do not operate or permit anyone else to operate your air compressor until the information contained in this

manual is read and completely understood. Please contact your distributor or our customer service department if you

have any questions on the proper use of your air compressor.

DIRECT-DRIVE ELECTRIC

Establish that the air compressor is ready to operate by reviewing the topics and information provided in the

-

and keep drain open for a few seconds after starting to warm up motor/pump assembly. Make sure the pressure

aintain top end tank pressure setting. Rotate

regulator adjustment knob counterclockwise until the gauge attached reads 0 PSI before attaching air hose and

accessory. Set working pressure by rotating regulator adjustment knob clockwise and lock in working pressure

to start or stop the air compressor. Never stop the compressor by unplugging it from the power source. Store

compressor in a warm/dry location and perform maintenance as indicated in manual.

VT20ST

Horsepower

2 HP

Tank Capacity

4.2 Gallon

Voltage

120 V

Pump-Up Time (0-125 PSI)

1:23

Hertz

60 hZ

Recovery Time (95-125 PSI)

:20

Phase

Single

CFM Displacement

5.5

Motor RPM

1700

Cu. Ft. Delivered @ 40 PSI

4.8

Stages

Single

Cu. Ft. Delivered @ 90 PSI

4.2

Amperage

13.5

Dimensions (LxWxH in)

19x16x17

Thermal Protection

Manual

Weight

62 lbs

Factory Settings

Oil Fill Amount

95-125 PSI

10 oz

Noise Level

Duty Cycle

79 dBA

Continuous