20

Rockwell Automation Publication IOLINK-UM001A-EN-P - August 2017

Chapter 3

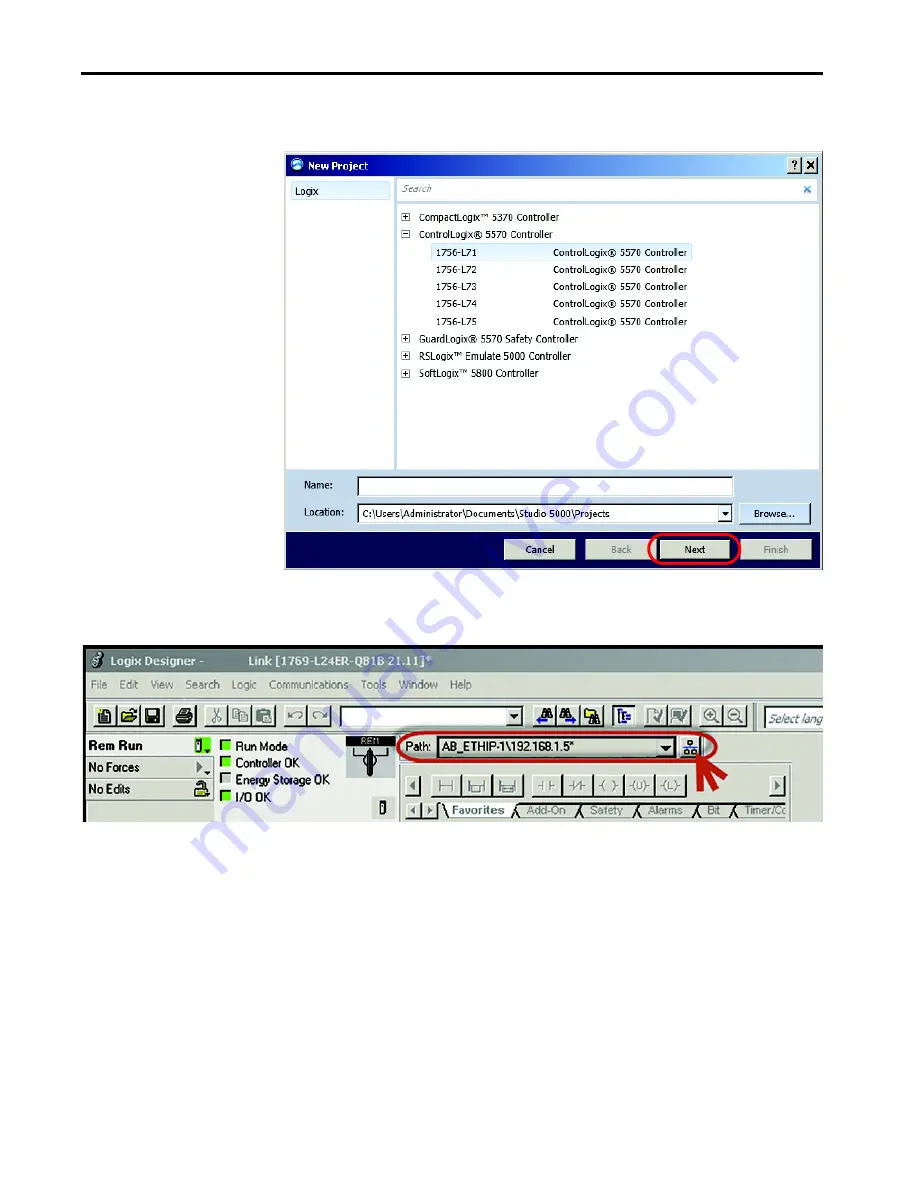

Create a Project

4. After selecting the controller, name the project and click Next. In this

example, the project name is “Project836P.”

5. Once the project opens up, configure the IP address of the controller to

help ensure communication. To configure the IP address, click the

browsing icon.

Project836P

Содержание Allen-Bradley 836P Series

Страница 1: ...IO Link for Solid state Pressure Switches Catalog Number 836P Dx User Manual OriginalInstructions...

Страница 22: ...22 Rockwell Automation Publication IOLINK UM001A EN P August 2017 Chapter 3 Create a Project Notes...

Страница 30: ...30 Rockwell Automation Publication IOLINK UM001A EN P August 2017 Chapter 5 Register the 836P IODD Notes...

Страница 45: ......