INSTALLATION INSTRUCTIONS-

WIRING-continue

Page 3

Red

Red

Red

Red

Red

Red

Red

Red

Black

Black

Black

Black

Brown

Brown

Brown

Brown

Brown

Brown

Brown

Brown

Red

Red

Red

Red

(to

(to

(to

(to

igniti

on)

Blue

Blue

Blue

Blue

Blue

Blue

Blue

Blue

Winch

Winch

Winch

Winch

Black

Black

Black

Black

Red

Red

Red

Red

Remote

Wireless remote

control

Solenoid

Yellow

Blue

Battery

Handlebar

remote

Master switch

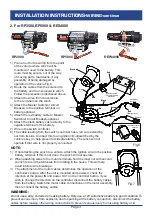

2. For RP3500,RP5000 & RES4000

RP2000 RP5000 REW4000

1) Plan a rout for the wiring from the point

of the vehicle where winch will be

mounted,or used to the battery. This

route must be secure, out of the way

of moving parts, road devris,or any

possibility of being damaged by

operation of the vehicle.Fig.6

2) Route the cables from the solenoid to

the battery and from solenoid to winch.

Follow the precautions discussed above.

3) Attach the wires from the solenoid

to the terminals on the winch.

4) Attach the Master Switch(or Circuit

Breaker) to the positive terminal on

battery-optional.

5) Attach the red battery cable to Master

Switch(or Circuit Breaker)-optional.

6) Attach the black battery cable directly to the

negative terminal of the battery.

7) Wire in the switch controller.

8) The cable leading from the switch controller has a red wire extending

out from its side. Connect this to an ignition circuit(switched by the

vehicle’s key) to help prevent accidental starting. The winch will not

operate if that wire is not properly connected.

optional

(Circuit Breaker)

Fig.6

NOTE:

1) If not attaching the winch to a vehicle, attach the ignition wire to the positive

battery terminal. If this is not done, the winch will not operate.

2

)

When attaching wires to the motor terminals, hold the inner nut with second

wrench to avoid the terminals from rotating in the house. This will help

avoid internal wire breakage.

3)

The attachment of the motor cables determines the operation of the

controller’s button. After the unit is mounted and powered, check the

direction of the power IN and power OUT on the controller button. If you

wish to change the direction on the controller, disconnect the battery cables

from the battery. Switch the motor cable connections on the motor assembly,

then reconnect the battery cables.

WARNING:

Fig.7

Do not use a dirty, corroded or leaking battery. Only use a 12V automotive battery in good condition.

To

prevent serious injury from explosion due to sparking at the battery connection, disconnect the battery

cables before making other wiring connections.To prevent serious injury from leaking battery acid.