11

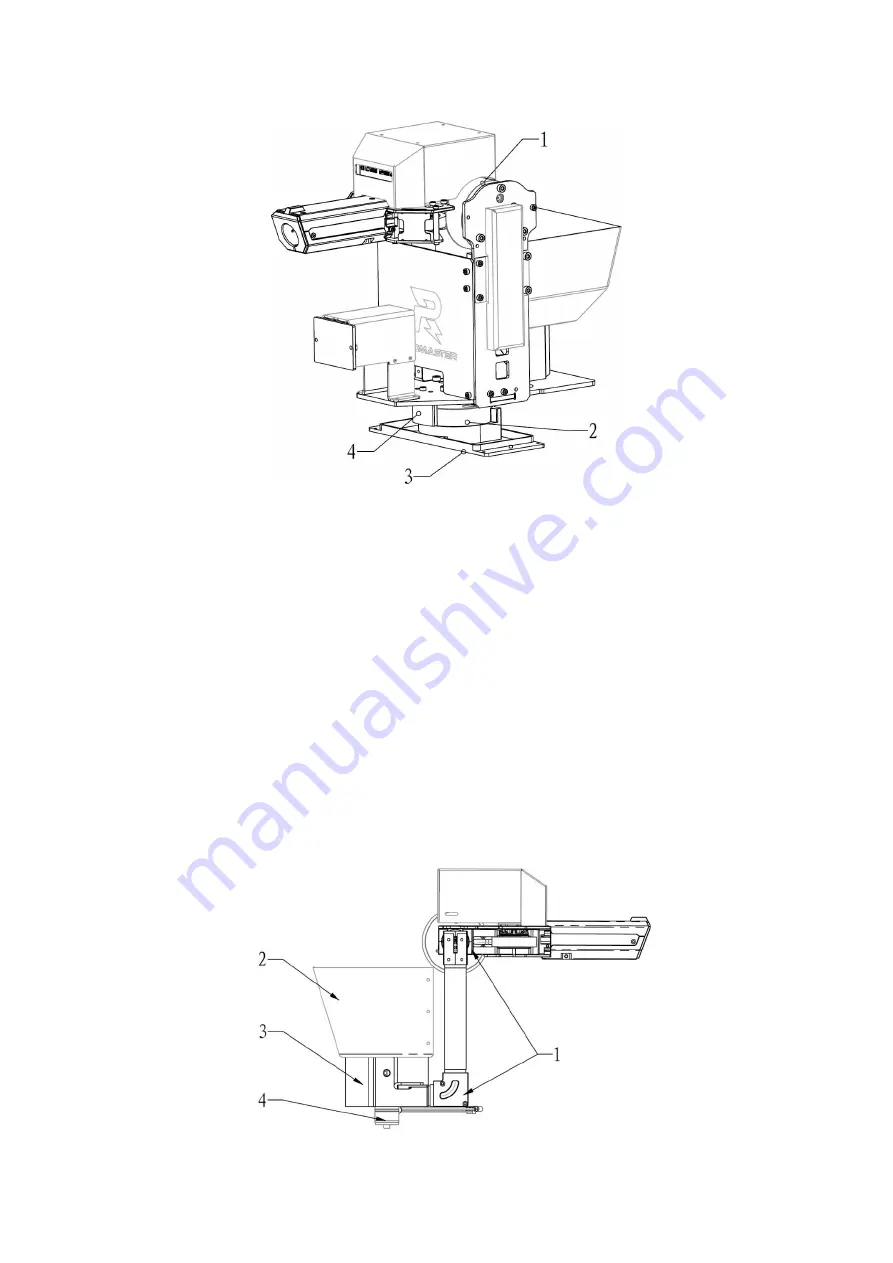

1. Pitch-axis motor 2. Yaw-axis motor

3. Gimbal base fastening fixture 4. Yaw-axis mechanical limit

There are four connectors linking the 2-Axis Gimbal Module and Chassis Module. The XT30 power cable is

connected to the Gimbal XT30 interface of the Referee System Power Management Module. The 2-pin CAN

connector is linked to the CAN interface of the Development Board Type C on the chassis. The aerial connector is

linked to the aerial interface of the Referee System Power Management Module. The RoboMaster C610 Brushless

DC Motor Speed Controller is connected to the Ammo-Booster XT30 interface of the Referee System Power

Management Module.

The 2-Axis Gimbal Module is propelled by direct drive. The driving motor is the RoboMaster GM6020 Brushless

DC Motor, and the ESC is integrated in the motor. For the detailed technical specifications of the motor and ESC,

see the “RoboMaster GM6020 Brushless DC Motor User Guide” in the reference document pack.

2.5

Projectile Supply Module

The robot receives projectile supplies through the lower section. The magazine is separated from the Launching

Mechanism, to increase the flexibility of the Launching Mechanism and the projectile load. The projectile load is

about 300 rounds, which can be partially modified as required. After the initial loading, you must wait for the feed

sprocket to fill the pipeline so that projectiles can be fired from the muzzle.