14

10-V1011

Z3200

Z3200

10-V1011

15

–

English

–

Deutsch

–

English

–

Deutsch

Lateral adjustment

of the scoring blade

(Fig.13-14)

Each time the main sawblade is replaced by a new one, or even a newly sharpened sawblade, the

scorer has to be adjusted to match the main sawblade teeth width. It is very important that this is done

in the correct way to ensure a clean cut, free of splintering.

The use of two piece scoring saws is best because they can easily be adjusted using spacer rings.

The lateral movement of the scorer sawblade is achieved by turning the knob (fig. 11,5) and the locking

(fig. 11,6).

After the lateral adjustment is done the scale (fig. 11,7) has to be set at “0”.

Figures 13 and 14 show the different possibilities :

1) Without the use of a scorer saw

2) Correct setting of the scorer saw but too deep

3) Too much to the right side

4) Correct setting of the scorer saw.

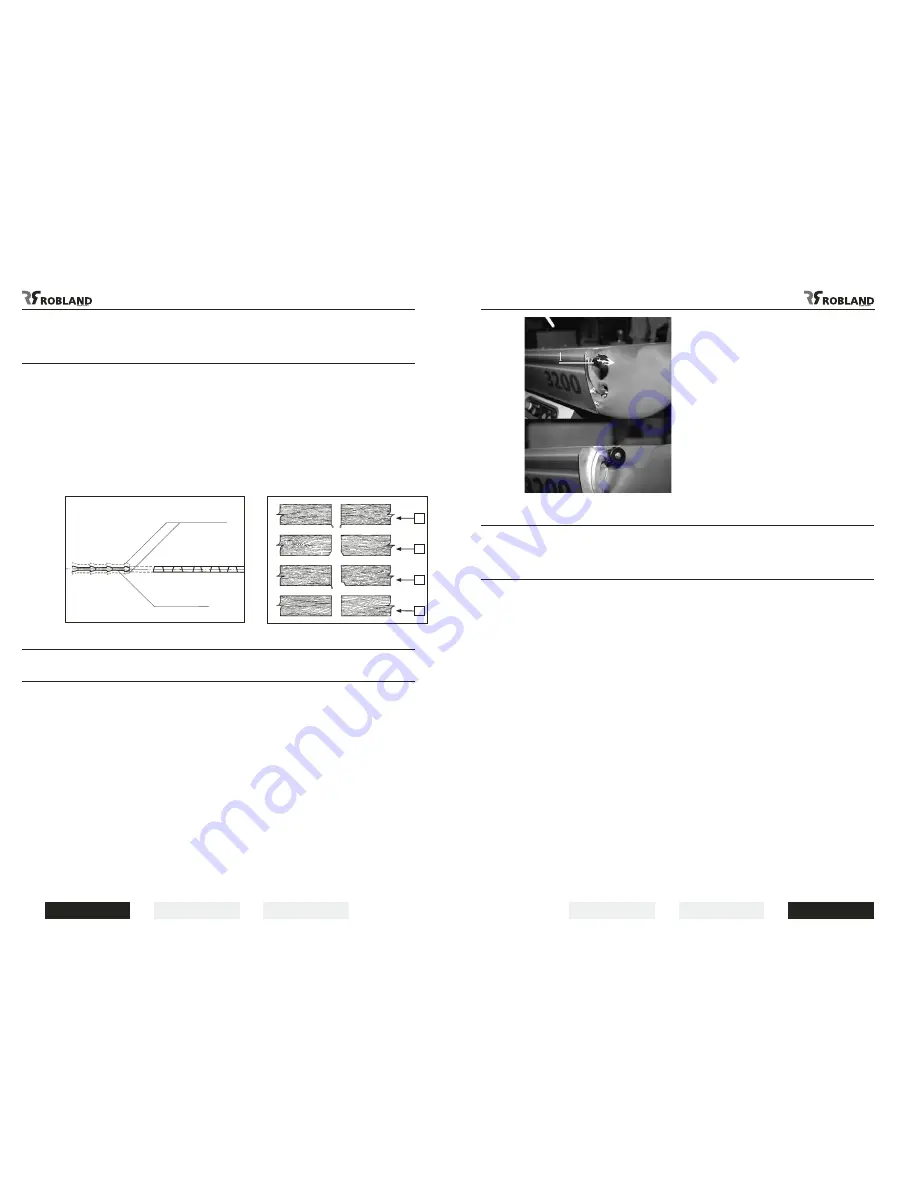

Blocking the sliding table

(Fig.15)

Blocking the sliding table (Fig.14)

-

The sliding table can be blocked in two positions and with one block-system. This is vital for

example by loading of the boards or cutting along the parallel guide. The system is located on the

front-side of the sliding table. Pull the button (1) in your direction and turn to the right to liberate the

table. Pull the sliding table till end, the table will be blocked automatically when arriving in the exact

position. Continue this way to start working.

-

When several movements are repeated consecutively, it is possible that the bearing cage between

the two profiles moves a little bit. We can note this as well by a reducing travelling distance of the

sliding table. To proceed and achieve the normal travelling distance of the sliding table, you can

adapt the position of the bearing cage: simply push the table with a few short, light pushes against

the buffer stop at the end of the sliding table until the position of the ball carrier is adjusted and the

table can be moved again along its full stroke.

Attention: cleaning and maintenance of the sliding table

It is vital to regularly blow away the saw- and other dust, collected between the sliding table

and the bearing cage. Push the sliding table to the end, to get a better reach towards the rails,

the bearing cage and gliding tracks. Oil serves to lubricate the sliding rails and is an extra

guarantee of good use and function.

Maintenance and lubrication

of the sliding table

It is highly recommended to clean the sliding table once a week, and to remove all sawdust and chips

which gradually slow down the sliding table. From both sides of the sliding table blow out the dust

accumulated between the two sections and on the ball carrier.

This can be done more easily and efficiently when the upper part of the sliding table is slid to the rear,

and must then be repeated with the upper part at the front end.

After all dust has been blown out, a thin oil with a teflon base or plain diesel oil should be sprayed onto

the steel V-liner strips on both the upper and lower part of the sliding table. Never use a thick oil or

grease ! This maintenance job will only take 10 minutes of your time, and will ensure the

machine gives full satisfaction.

1

2

3

4

NOT CORRECT

CORRECT

Fig.13

Fig.15

Fig.14