Rhein - Nadel Automation GmbH

8

Date: 14.04.2014

VT-BA-GL-GB

Notice

The resonant frequency of the linear feeder may not correspond to the mains frequency

In case the conveying capacity decreases after loosening the spring fastening screw, proceed as described under

point 5.1

.

In case, however, the conveying capacity, increases, proceed as described under

point 5.2

.

Notice

The adjustment is, however, more easy with an electronic frequency converter, which you can buy from

our range of accessory parts.

The linear feeder should be adjusted that the required conveying capacity is achieved at a controller position of

approx. 80% at the control unit.

5.1

The conveying speed decreases?

Mount additional springs (with distance plates). Start with one additional spring (with washer) at one spring

assembly. In case the conveying speed still

decreases, although an additional fastening screw is loosened,

install one additional spring in each individual spring assembly (one after the other).

5.2

The conveying speed increases?

Remove the springs. First remove one spring (with washer) from a spring assembly. In case the conveying speed

still increases, although an additional fastening screw is loosened, remove one spring from each individual spring

assembly (one after the other).

Notice

The side plates must always be mounted for test runs

Notice

At a turning knob position of 100 % at the control unit and correctly adjusted magnetic gap the magnet

may not dash against the armature when switching on the device.

The aim of the adjustment is:

If the required conveying speed is achieved at a controller position of 80 %, the conveying speed must always

decrease when the spring fastening screw is loosened.

Notice

Take care that the number of springs per spring assembly does not differ by more than 2-3 springs.

After removing and mounting of the leaf springs the linear feeder must be readjusted.

Adjustment of the linear feeder type GL 01:

Tighten the spring fastening screws with the specified tightening torque (see "technical data" chapter 1). Control and

keep to the mounting dimension (oscillator height) of 85 mm at all four edges of the linear feeder. Before starting

the side plates must be mounted.

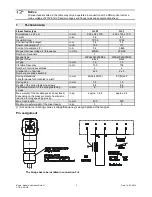

A

Conveying speed

B

Resonant frequency of the system

C

Resonance curve (not true to scale)

D

Spring power