Rhein - Nadel Automation GmbH

6

Date: 14.04.2014

VT-BA-GL-GB

Notice

Detailed information on the complete range of control units may please be taken from the operating

instructions for control units

All control units have got two main operating elements:

By the

main switch

the linear feeder is switched on or off.

By the

turning knob

the conveying caacity of the sorting unit is set.

Frequency controller

can also be used for tuning vibratory linear feeders: Exact tuning instructions can be found in

our operating instructions for frequency control units.

4

Transport and mounting

Transport

Notice

Take care that the linear feeder cannot dash against other things during transport

The weight of the linear feeder is taken from the table „technical data“ (chapter 1.)

Mounting

The linear feeder should be mounted on a stable substructure (available as accessory part) at the place where it is

used. The substructure must be dimensioned in a way that no vibrations of the linear feeder can be carried away.

Linear feeder are fastened to the vibration buffers from below (part G in the general drawing chap. 3). The following

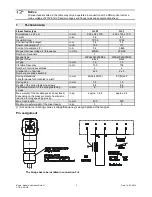

table give you a summary of the bore date of the various types:

Linear feeder type

Length in mm

Width in mm

Vibration buffer thread

GL 01

152

40

M4

GL 1

285

70

M6

Table bore data

Make sure that the linear feeder cannot come into contact with other devices during operation.

Further details on the control unit (bore plan, etc.) are please taken from the operating instructions of the control unit

separately delivered.

5.

Starting

Preparations

Notice

Ensure that the frame ( stand, base, frame etc.) is connected with the ground wire. (PE) If

necessary, predection earthing on spot should be provided.

Check, whether

the linear feeder stands in an isolated position and does not come in contact with a solid body

the linear track is fixedly screwed down and adjusted

the connecting cable of the linear feeder is plugged in at the control unit.