Instruction Manual IM‐116

CUSTOMER'S INFORMATION BOX

CONTENTS ARE INDEPENDENT OF RIVERHAWK DOCUMENT CONTROL

215 Clinton Road

New Hartford, NY 13413

Tel: +1 315 768 4855

Fax: +1 315 768 4941

Email: [email protected]

REV

373A4028

GE DRAWING NUMBER

Revision H

Page 15 of 29

CAUTION

DO NOT EXCEED THE MAXIMUM PRESSURE VIBROSCRIBED ON THE PULLER BODY. Excessive

pressure can damage the stud and the puller screw

For the procedures of Section 9.3 excessive stretch variation or low stretch values can be

corrected by retensioning all or selected studs to the pressure values stated in the above table.

Have final stretch values approved by the supervisor responsible for the installation.

10.0 Thread Locking

Once pulling and tensioning is complete all studs and nuts must be locked in position. The lock

nuts used in the turbine/coupling and coupling/generator connections employ a mechanical

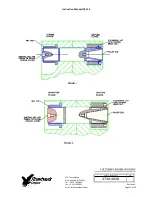

locking feature. These mechanical lock nuts have two set screws located on the top face, see

Figure 4.

Before threading the nut onto the stud check to be certain that the set screws are free to turn.

Once the nut is seated torque the set screws to the values specified in the following table.

When seated and torqued to the values specified the load created by the set screw displaces

the thread of the nut in the area of the web creating the desired locking action.

Stud Size

Set Screw Size

Torque

2.784"

[71 mm]

3/8"‐24 UN

200 in∙lbs ‐ 250 in∙lbs

[22.6N∙m – 28.2 N∙m]

2.283"

[58 mm]

1/4"‐28 UN

80 in∙lbs ‐ 90 in∙lbs

[9.0 N∙m – 10.2 N∙m]

11.0 Stud/Nut removal

Removal is accomplished as follows:

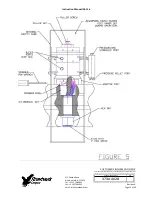

1.

Using a wire brush and shop air clean the internal tapered thread of the stud to remove

any debris/deposits which may have accumulated during service. (see section 5.2.1)

2.

With an Allen‐wrench loosen the two locking set screws but do not remove from the nut

see Figure 4.

3.

Install the appropriate puller tool to the stud as described in Section 8.0.