!"# $%&' ()()*+

a) Joint S-1R coupler with the hose end coupler S-1H.

Joint ROC-13R coupler with the hose end coupler ROC-13H.

b) Take out the cap of

air breather. Insert the end of coupler to the hole of air breather, and

retrurn the displaced oil to the reservoir.

c Shift the lever of

air shut-off valve to the START side, then open and close

shut-off

!

valve. Repeat these inching procedure.

,% -'.'/&' 01' /)- )* 01' 23.)*4'-

"

If you release the air when the pump, cylinder and hose is connected, extend the cylinder piston fully,

then put the cylinder upside down, and operate the cylinder by pumping the oil. Air will be released to

the reservoir.

!5# $)+1 (-'&&6-' &0''. ()(' ()()*+

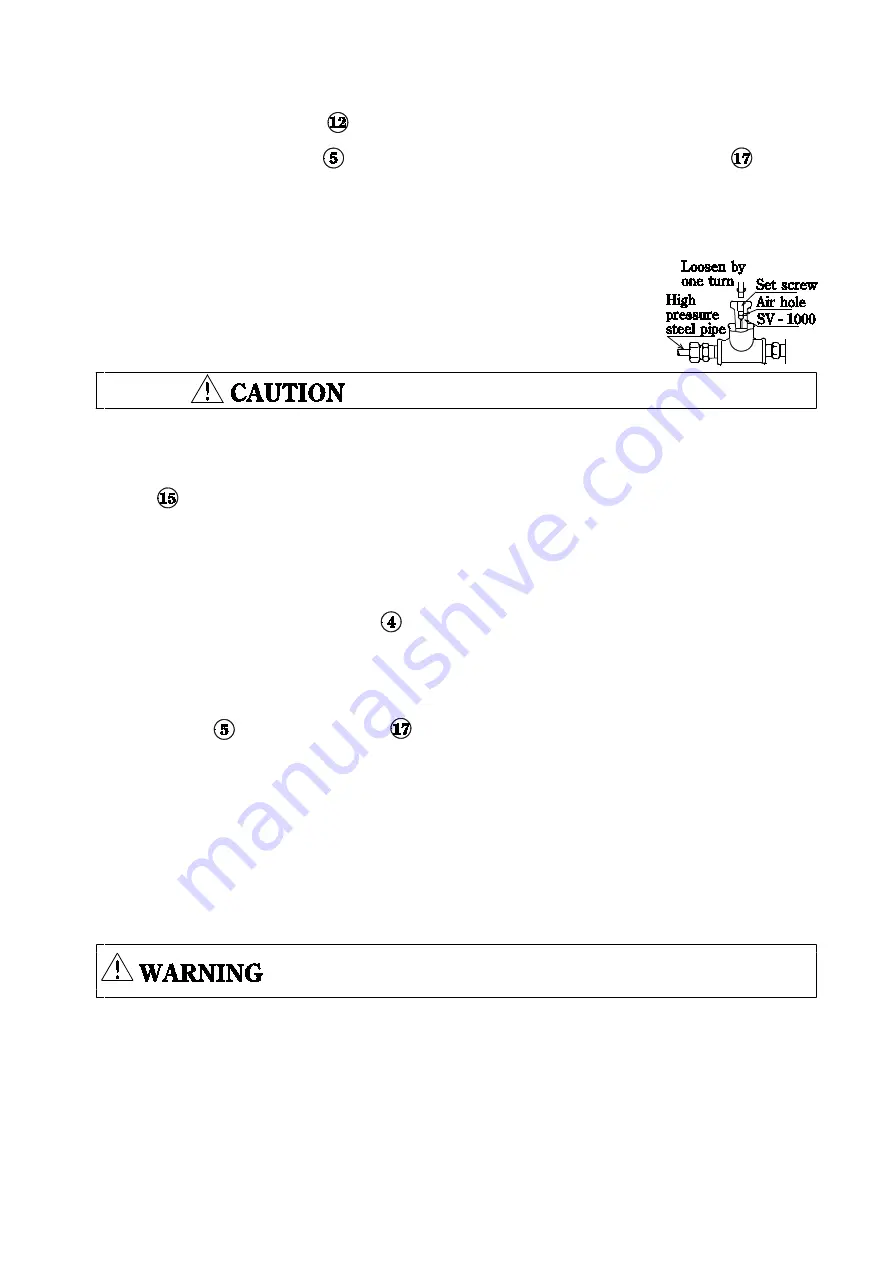

Install Model SV

!

1000 air releasing valve at the end of

steel piping.

a) Loosen the screw of SV

!

1000 by one turn.

b) Repeat inching until the working oil flashes out from the air hole.

2#

7%8'- 01' /)- -'.'/&)*+ (%-0 %9 :;

!

<=== >)01 >/&0' 2.%01.

d) Tighten the set screw of SV-1000.

!@# A* 2/&' %9 0'&0 -6*

Set

high pressure safety vale at 20 MPa {204 kgf/cm } initially, and check the oil leakage. Then

2

increase the pressure to 30MPa, and 40MPa and upto the operating pressure gradually. (See page 10

How to Adjust High Pressure Safety Valve.)

B. C/)*0'*/*2'

!<# C/)*0'*/*2' D'9%-' %('-/0)%*

(A) Check the air pressure by use of

air pressure gauge. The pressure should be 0.55 to 0.7 MPa

5.6 to 7.1 kgf/cm .

#

$

2

(B) Check if the oil volume is correct or not by retracting the cylinder piston completely and check if the

oil level can be seen from the port or not. If not, refill oil upto the upper line of the oil level gauge.

(C) Operate the pump more than one (1) minute under no load condition, and check if unusual noise,

unusual vibration, or other unsusual conditions happen or not.

(D) Operate

air shut-off valve and

shut-off valve to operate cylinder, and to increase the pressure

of the cylinder, so as to check if unsual conditions happen or not.

(E) Check if any oil leakage from the pipings and equipment happens or not, and shoot the trouble.

(F) Also refer 6. Cautions.

!E# C/)*0'*/*2' 6*4'- %('-/0)%*

Check the following items, and if unusual conditions happen, stop the pump operation, and shoot the

trouble.

(A) Is there any trouble on valve operation and pressure increasing?

(B) Is there any oil leakage from the piping and equipment?

(C) Is there any unusual noise, vibration, or smell?

F''( />/3 01' (./2' 9-%G >1)21 01' 1)+1 (-'&&6-' %). )& H'00)*+ %60.

,1' %). G/3 ()'-2' 01-%6+1 3%6- 1/*4I /*4 3%6 G)+10 D' )*H6-'4 1'/8).3.

!@# C/)*0'*/*2' /90'- %('-/0)%*

(A) Be sure to cut off the air source.

(B) Check if oil leakage or other unusual conditions exist or not. If exist, shoot the troubles.

(C) Clean out this pump after operation.

!J# ,% 21/*+' 134-/6.)2 >%-K)*+ %).

(A) Change oil at least once a year. Also change oil at the following cases;

a) Contamination of dusts

b) Malodor happens

c) Contamination of water, and blooming of oil

d) Degradation and browning

- 9 -

Содержание ON-5H-18

Страница 1: ......

Страница 5: ...4 0 0 0...

Страница 6: ...0 1 0 5...

Страница 13: ...0 1 2 0 3 0 0 45 2 67 8519 12...

Страница 16: ...0 1 2 3 2 2 45 67 89 7544 6 15...