Manuale CT Jolly e Poker (Cod.CARTTURBINA062014) pag.8

17 -REGULATIONS TO OPTIMISE THE APPLICATION OF MATERIALS .

THERE ARE 3 TYPES OF REGULATION:

PLEASE NOTE: In addition to the information supplied by item 15 and 16, please acquire the following data

1

ST

TANK PRESSURE:

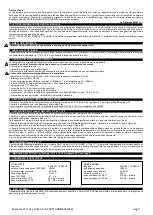

Tipe of material Working pressure Use of accessories .

(*) The system is designed to power off/on the compressor automatically according to the pressure in the tank.

ATTENTION:

It is recommended not to exceed 4 bars.

Never open the pressurised tank during the operation of the spray system, but only after having completely discharged pressure by

using the proper vent and safety valve (14) and by pulling the relative ring. Pay special attention to the lever faucet (20).

2ND

– PRODUCT FLOW RATE:

for particularly fluid products

– without varying the tank pressure, you can increase or decrease the product

quantity to be applied by acting on the product quantity regulator of the spray gun (32). See the spray gun manual

3RD

– FINISH DEGREE:

To optimise spraying, act on the air quantity regulation (33) to vary the air/product proportion for a better finish while

keeping the tank pressure and product flow rate unchanged. See the spray gun manual

18 - AFTER WORKING AND CLEANING Cart Turbine (see the general images on page 2) .

To keep the Cart Turbine system efficient and operating, carry out the following procedures at the end of work:

1.

Power off the turbine by pressing its switch on the control panel (11).

2.

Power off by means of the switch (26) on the socket unit.

3.

Depressurise the tank by means of the safety/vent valve (14) on the tank cover (15). Lift it and wait for air to come out

completely from the tank (4).

4.

Remove the tank cover (15) and let the paint flow out of the product hose inside the tank by gravity while keeping the spray gun lever (34)

down.

5.

Empty the residual paint from the tank into a container holding the suction unit (21) upwards (

) for subsequent re-use and proper

disposal.(page 2, image D). P.S. for a correct functioning pay attention to keep the vent and safety valve clean (18A).

6.

Fill in the tank (4) with water or solvent / thinner according to the type of product in use.

7.

Re-close the tank cover (15).

8.

Power on again by means of the main switch (26).

9.

Wait for the pressure to increase as far as enough to carry out the cleaning cycle and, therefore, enable the water or solvent/thinner to

reach the spray gun.

10.

Let it act for some minutes; then empty all the tank in a container for proper disposal of the waste material.

Never start the TMR turbine.

11. If necessary, repeat the cleaning cycle (phase from 1 to 10) more than once to let the water or solvent/thinner flow out without any

product residue.

12. In the end, power off (26).

13. Empty, clean and dry all the parts that may have come in contact with the painting product.

14. Place the Cart Turbine in a dry environment sheltered against water and humidity.

● Note: never leave water, the solvent/thinner inside the tank, the hose and the spray gun for a long period to avoid compromising the functionality

thereof for any further use.

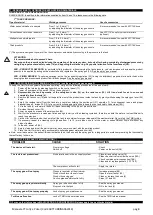

19 -USEFUL TIPS IN CASE OF MALFUNCTION (*) .

PROBLEM CAUSE SOLUTION

.

(*) For any other failure due to MALFUNCTION OR NON-OPERATION, please apply to an authorised retailer .

The device will not start.

No mains voltage

- Check

Switch off

- Power on the switch (26)

The tank is not pressurised

No hermetic seal in the air supply system

- Close air and safety valve (14)

- Clean check air valve inside the union (18A)

- Check compressor air connection (18B)

- Clean and/or replace gaskets (13-17-22)

The compressor will not start

- Apply to a retailer

The spray gun will not spray

Pressure regulator at the minimum

- Increase pressure (28)

Product hose lever faucet closed

- Open the lever faucet (20)

Product hose clogged

- Clean or replace the hose (9)

Suction pipe and paint outlet dirty

- Clean (21 and 23)

The spray gun sprays intermittently

Spray gun in bad condition / dirty

- See the spray gun manual

No product in the tank

- Fill in the tank (4)

The spray gun will not spray properly

Lack of spray gun maintenance

- See the spray gun manual

Turbine malfunction

Lack of TMR turbine maintenance

- See the TMR turbine manual

!

Water based varnishes / enamels

From 1 to 1.5 bars (*)

by adjusting the diameter of the spray gun nozzle

It is recommended to use with ATC15K hose.

Solvent based varnishes / enamels

From 1 to 1.5 bars (*)

by adjusting the diameter of the spray gun nozzle

Use ATC17K hose for solvent materials

(optional)

Wall paints and waterpaints

From 1.5 to 2.5 bars (*)

by adjusting the diameter of the spray gun nozzle

It is recommended to use with ATC16K hose.

Thick products

From 2.5 to 3.5 bars (*)

by adjusting the diameter of the spray gun nozzle

It is recommended to use with ATC16K hose.

!