3

ance at all times.

Proper footing and balance enables

better control of the tool in unexpected situations.

•

Use safety equipment. Always wear eye protection.

Dust mask, non-skid safety shoes, hard hat, or hearing

protection must be used for appropriate conditions.

Tool Use and Care

•

Do not use tool if switch does not turn it ON or

OFF.

Any tool that cannot be controlled with the switch

is dangerous and must be repaired.

•

Disconnect the plug from the power source before

making any adjustments, changing accessories,

or storing the tool.

Such preventive safety mea-

sures reduce the risk of starting the tool accidentally.

•

Store idle tools out of the reach of children and

other untrained persons.

Tools are dangerous in

the hands of untrained users.

•

Check for misalignment or binding of moving

parts, breakage of parts, and any other condition

that may affect the tool's operation. If damaged,

have the tool serviced before using.

Many acci-

dents are caused by poorly maintained tools.

•

Use only accessories that are recommended for

your tool.

Ac cessories that may be suitable for one tool

may become hazardous when used on another tool.

•

Keep handles dry and clean; free from oil and

grease.

Allows for better control of the tool.

Service

•

Tool service must be performed only by qualified

repair personnel.

Service or maintenance performed

by unqualified repair personnel could result in injury.

•

When servicing a tool, use only identical replace-

ment parts. Follow instructions in the Maintenance

Section of this manual.

Use of unauthorized parts or

failure to follow maintenance instructions may create a

risk of electrical shock or injury.

Specific Safety Information

WARNING

Read this operator’s manual carefully before using

the 535 Threading Machine. Failure to understand

and follow the contents of this manual may result in

electrical shock, fire and/or serious personal injury.

Call the Ridge Tool Company, Technical Service

Department at (800) 519-3456 if you have any questions.

Foot Switch Safety

Using a threading machine without a foot switch

increases the risk of serious injury. A foot switch

provides better control by letting you shut off the

motor by removing your foot. If clothing should

become caught in the machine, it will continue to

wind up, pulling you into the machine. Because the

machine has high torque, the clothing itself can bind

around your arm or other body parts with enough

force to crush or break bones.

Machine Safety

•

Threading Machine is made to thread and cut

pipe or bolt and to power roll grooving equip-

ment. Follow instructions on proper use of this

machine. Do not use for other purposes such

as drilling holes or turning winches.

Other uses or

modifying this power drive for other applications may

increase the risk of serious injury.

•

Secure machine to bench or stand. Support long

heavy pipe with pipe supports.

This practice will

prevent tipping.

•

Do not wear gloves or loose clothing when oper-

ating machine. Keep sleeves and jackets buttoned.

Do not reach across the machine or pipe.

Clothing

can be caught by the pipe or machine resulting in

entanglement and serious injury.

•

Operate machine from side with REV/OFF/FOR

switch.

Eliminates need to reach over the machine.

•

Do not use this machine if the foot switch is bro-

ken or missing.

Foot switch is a safety device to

prevent serious injury.

•

Keep hands away from rotating pipe and fittings.

Stop the machine before wiping pipe threads or

screwing on fittings. Allow the machine to come to

a complete stop before touching the pipe or

machine chucks.

This practice will prevent entan-

glement and serious injury.

•

Do not use this machine to make or break fittings.

This practice is not an intended use of the machine and

can result in serious injury.

•

Tighten chuck handwheel and engage rear cen-

tering device on the pipe before turning on the

machine.

Prevents oscillation of the pipe.

•

Keep covers in place. Do not operate the ma chine

with covers removed.

Exposure to moving parts may

result in entanglement and serious injury.

•

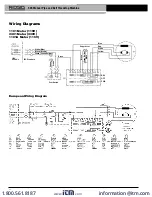

Lock foot switch when machine is not in use

(Figure 1).

Avoids accidental starting.

535 Manual Pipe and Bolt Threading Machine

WARNING

www.

.com

1.800.561.8187