• This setting must be selected and displayed before you can do the installation procedure.

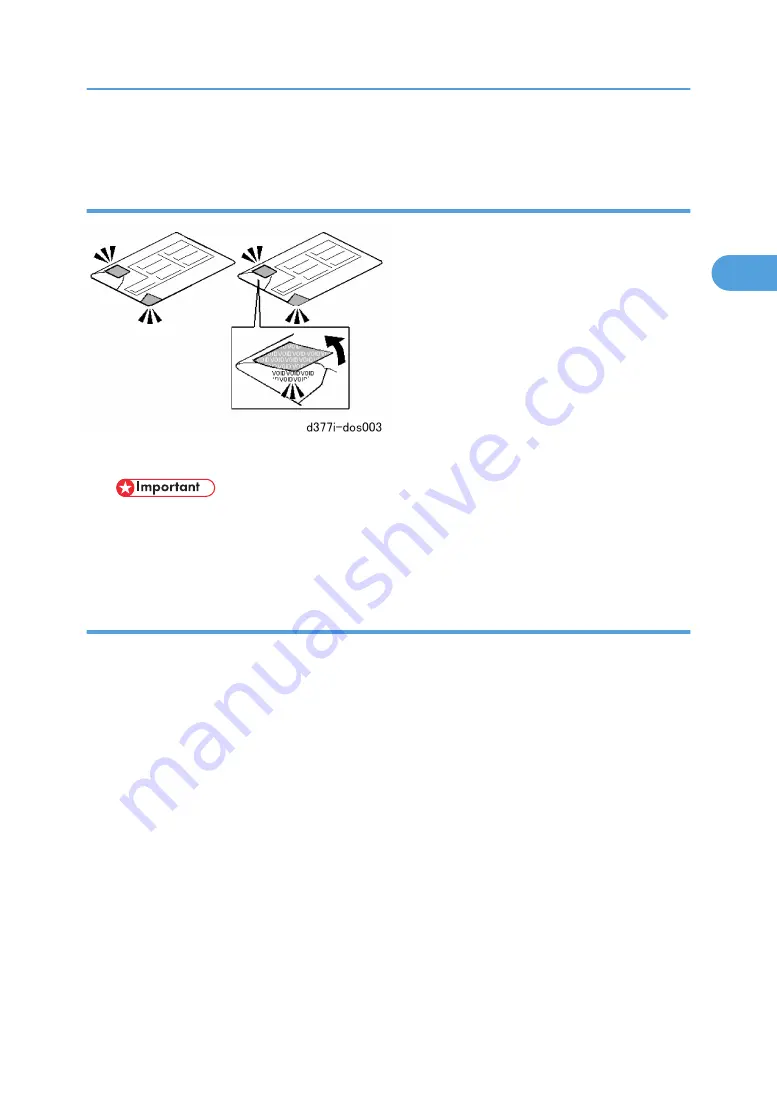

Seal Check and Removal

1. Check the two seals and confirm that they are firmly attached.

• If you see "VOID" on the tapes this means that the seals have been disturbed. If the "VOID"

notations are visible, do not use the SD card for this installation. Contact your sales division.

2. Remove the seals. The silver "VOID" notations become visible only after you have removed the seals.

Installation Procedure

Before doing the procedure, turn off the main power switch and unplug the machine from its power source.

1. Make sure that the machine is switched off and disconnected from its power source.

2. Disconnect the network cable.

3. Turn the main power switch on.

4. Turn the operation switch and main power switch off.

5. Remove the SD card slot cover (

x1).

6. Check the security tape on the wrapping.

• If you see "VOID" on the security tape this means that the tape has been disturbed.

• If the "VOID" notations are visible, do not use the SD card for this installation. Contact your sales

division

7. Remove the security tape from the SD card wrapping.

8. Insert the DOS SD card into Slot 1.

MFP Options

205

2

Содержание BE-C1 D046

Страница 1: ...Model Be C1 Machine Code D046 D049 Field Service Manual August 2008 Subject to change...

Страница 2: ......

Страница 22: ...Configuration 3 Main Machine Folder FD6500B B890 2 Installation 20 2...

Страница 67: ...Paper Cassette Type 7140 D395 65 2...

Страница 81: ...6 Attach the size decals 7 Attach A Original stoppers B Original guides Tray and Stacker Options 79 2...

Страница 127: ...10 Open cover A 11 Attach the large mylars B to cover N5 Bridge Unit BU6500 D407 Folder FD6500A B889 125 2...

Страница 173: ...3 Remove the rear cover A of the cross fold unit x3 4 Remove cover A x1 Folder FD6500B Cross Folder B890 171 2...

Страница 180: ...23 Reattach cover A x1 24 Reattach cover A x3 2 Installation 178 2...

Страница 217: ...Installation 1 Remove the rear cover of the machine to expose the controller box A x8 MFP Options 215 2...

Страница 256: ...2 Installation 254 2...

Страница 257: ...3 Preventive Maintenance Preventive Maintenance The PM tables are included in the Appendices 255 3...

Страница 258: ...3 Preventive Maintenance 256 3...

Страница 268: ...3 Remove the controller box faceplate 1 x6 4 Remove the controller box cover 1 x11 4 Replacement and Adjustment 266 4...

Страница 286: ...8 Remove the left scanner plate 1 x2 9 Remove the right scanner plate 1 x2 4 Replacement and Adjustment 284 4...

Страница 287: ...10 Remove the CIS unit 1 Scanner Unit 285 4...

Страница 291: ...5 Remove the right exposure glass plate 1 x2 6 On the left pull out the exposure glass 1 Scanner Unit 289 4...

Страница 296: ...9 Remove the original junction gate 1 4 Replacement and Adjustment 294 4...

Страница 362: ...9 On the right remove the screws 1 and bearing 2 x2 10 Remove the hot roller 1 4 Replacement and Adjustment 360 4...

Страница 371: ...4 Remove screws 1 and 2 on the right and left x2 5 Remove the registration idle roller panel 1 Sensors Switches 369 4...

Страница 374: ...2 Disconnect the sensor assembly 1 x1 3 Remove the sensor 2 x1 Pawls x4 4 Replacement and Adjustment 372 4...

Страница 388: ...4 Use a wrench 1 to remove the BCU stand screws x3 5 Remove the IPU 2 4 Replacement and Adjustment 386 4...

Страница 446: ...6 Troubleshooting 444 6...

Страница 447: ...Model Be C1 Machine Code D046 D049 Appendixes August 2008 Subject to change...

Страница 448: ......

Страница 462: ...1 Appendix Specifications 14 1...

Страница 463: ...2 Appendix Overview Overview Machine Layout 1 Image Writing Unit 15 2...

Страница 484: ...Drum Drive Section 1 Drum Drive Gear Silicone Grease G501 4 Appendix Preventive Maintenance Tables 36 4...

Страница 528: ...7 Appendix Jam Detection 80 7...