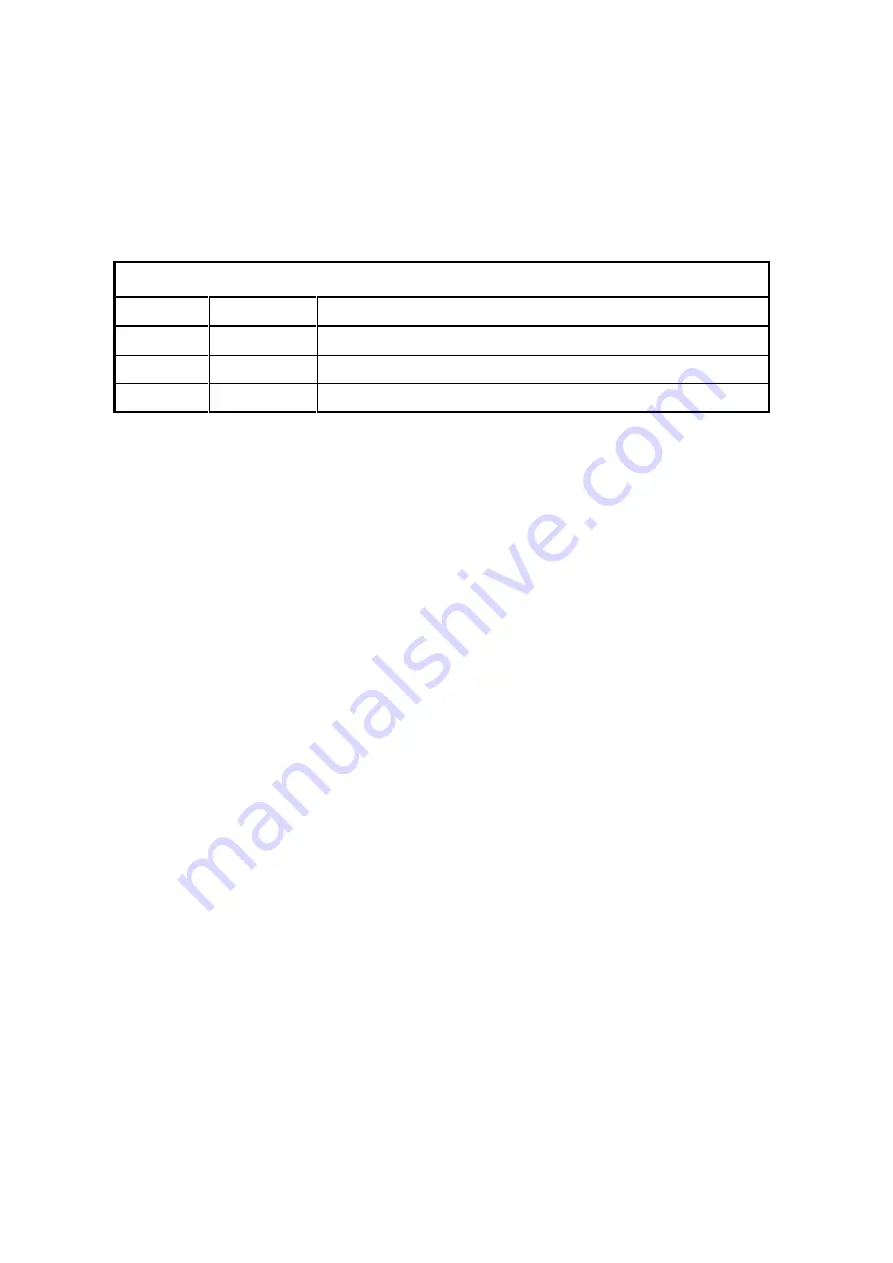

TROUBLESHOOTING

TROUBLESHOOTING REVISION HISTORY

Page

Date

Added/Updated/New

5

09/07/2006

Updated Information – Paper Jam Codes

26 ~ 27

11/21/2006

Updated Information – Service Call Conditions

51 ~ 52

09/07/2006

Updated Information – Service Call Conditions