Assemble Deck Modules

3

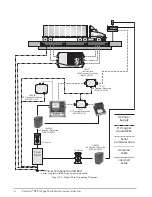

2.0 Assemble Deck Modules

The modules are designated either as an end module

or a center module. All two-module scales will have

two end modules, while longer scales will have two

end modules and one or more center

module (see

diagram below).

Figure 2-1. Center and end modules.

In a three module scale, the end module is the first to

be positioned on setting blocks followed by the center

module. The last module to be assembled is an end

module. Scales with more than threee modules will

have additional center modules installed. As an

example, a 100' scale would have two end modules

and three center modules.

2.1 Place End Module A

Place one 12-1/4" temporary setting block on the top

of each pier and position them so that they will not

interfere with the installation of the load cell mounts.

The scale module should be 3/4" away from the

bulkhead ramp and 3/4" from each pit wall side (see

figure on right). By using the 12-1/4" blocks, the top

of the main beam will be approximately 6-1/3" below

the top of the pit.

2.2 Place and Attach Center Module

NOTE:

To assist in easy assembly of the center module, make

sure that both modules have direct end-to-end surface

contact.

1. Place four 12-1/4" setting blocks on top of the

piers in the center sections.

2. Position and place the center module on the

setting blocks, making sure that both the end

module and center module end plates are

aligned.

3. Check that the module is centered side-to-side

in the pit.

NOTE:

At the installer’s discretion, install the center section

with the J-box on the near side to the scale house.

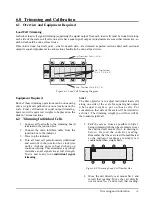

4. When both modules are aligned, insert the top

three 1-1/8" bolts with flat washers, lock

washers and nuts on the outside of the beam.

(Leave out the bottom bolt to facilitate load

cell mount installation).

NOTES:

•

Tighten bolts and nuts finger tight until all modules

are in place.

•

A long pry bar can be used to make small

adjustments in module alignment, but it is easier to

leave the second module attached to the crane for

making small alignment changes.

5. Install the three top bolts, washers and nuts on

the inside of the beam. Install the bolts,

washers and nuts on the opposite beam using

six bolts, washers and nuts. Tighten only

finger tight.

NOTE:

Do not install the bottom bolt at this time.

Figure 2-2. Top bolts, washers, and nuts installed.

6. If required, place and install any additional

center modules in a similar manner.

7. Install the remaining end module on four

setting blocks ensuring the end beams are

aligned with and in direct surface contact with

the center module.

Figure 2-3. Module installation.

8. Center the module side-to-side and check that

the end of the main beam is 3/4" from the end

of the concrete pit wall. Install and tighten the

three top bolts on each beam (inside and

outside) finger tight as in the previous

operation.

NOTE:

Do not install the bottom bolt at this time.

CENTER

END

END