14 |

P a g e

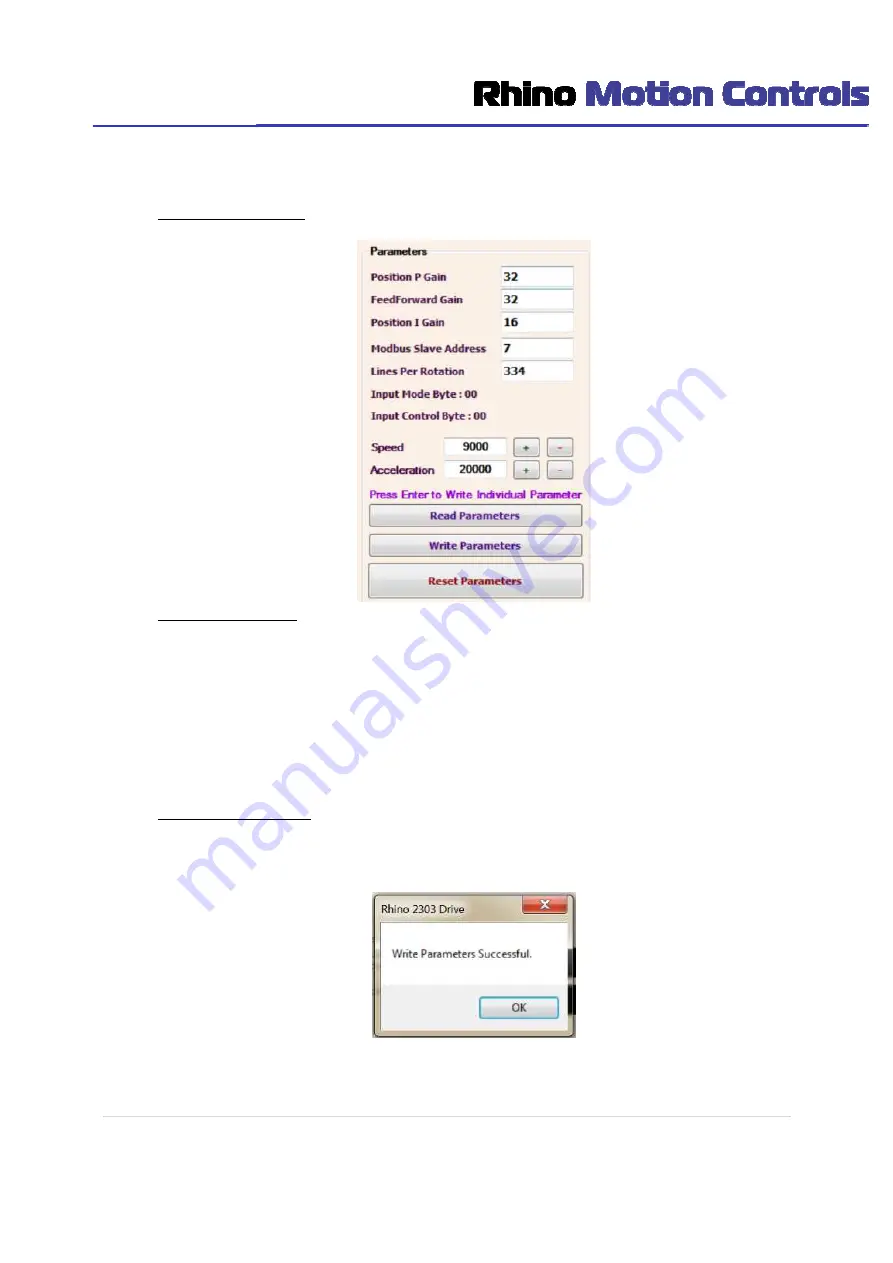

Parameters

READ PARAMETERS

"

Read Parameters

" is used to read current parameters of drive.

SET A PARAMETER

•

Pressing 'Enter' on text box will change the parameter in drive but it will not be saved permanently.

'Write Parameters' button must be clicked to save all parameters permanently.

•

Set Position Proportional gain, Velocity Feed Forward gain and Position Integral Gain as per

requirement. These can be used to remove vibrations and making movement of motor accurate.

•

Set Modbus slave address and lines per rotation. Lines Per Rotation is very important because it does

have effect on indication of speed feedback.

•

If slave address is changed the software will automatically change the slave id of currently connected

device.

•

Set Speed and Acceleration as per the requirement of application.

WRITE PARAMETERS

Once all the parameters are entered and tested, click on "

Write Parameters

" to save all parameters in drive.

These parameters will be changed permanently. Notification will be shown as below when all parameters

are written successfully.