8

LEAK TESTING

— The water heater and its gas

connections MUST be leak tested at normal oper-

ating pressure before it is placed in operation. Turn

ON the manual gas shut-off valve near the water

heater. Use a soapy water solution to test for gas

leaks at all connections and fittings. Bubbles indi-

cate a gas leak that must be corrected. The water

heater factory connections to the gas valve should

also be leak tested after placing the water heater

in operation.

NEVER

use open flame to test for gas leaks, as

bodily injury or property damage could result.

PRESSURE TESTING THE GAS SUPPLY SYSTEM

— The water heater and its manual gas shut-off

valve MUST be disconnected from the gas supply

piping system during any high pressure testing of

that system at pressures in excess of 1/2 psi (14”

w.c. / 3.5 kPa).

The water heater MUST be isolated from the gas

piping system by closing the manual gas shut-off

valve during any pressure testing of the gas supply

piping at pressures equal to or less than 1/2 psi

(14” w.c. / 3.5 kPa).

6. CONDENSATE

This is a condensing high efficiency appliance,

therefore this unit has a condensate removal

system. Condensate is nothing more than water

vapor, derived from the combustion products. This

condensate does have a low pH and condensate

removal must comply with all local codes. It is

very important that the condensate line is sloped

away from and down to a suitable inside drain. If

the condensate outlet on this unit is lower than the

drain, you must use a condensate removal pump.

It is also very important that the condensate line is

not exposed to freezing temperatures, or any other

type of blockage. Plastic tubing should be the only

material used for the condensate line. Steel, brass,

copper, or other metals will be subject to corrosion

and deterioration. A second vent may be neces-

sary to prevent condensate line vacuum lock if a

long horizontal run is used. Also an increase to 1"

tubing may be necessary.

CONDENSATION ELBOW ASSEMBLY

Prior to connecting the exhaust vent pipe, the

condensate elbow assembly (supplied, but not

factory installed) must be connected to the ex-

haust pipe on the water heater (See Figure 2).

The free end of the 3 x 3 x 1.5 PVC reducing tee

slip fits over the 3” exhaust pipe on the water

heater. For maximum durability and sealing, use

a high heat silicone sealant appropriate for di-

rect vent appliances (rated for at least 150° F).

Apply a bead of silicone around the inside of

the free end of the reducing tee. Do the same

around the end of the exhaust pipe on the

heater. Push the end of the reducing tee onto

the exhaust pipe as far as the tee allows. The

orientation of the condensate elbow assembly is

critical for proper venting of gas and drainage of

condensate. See Figure 3 for proper final orien-

tation of the assembly.

INSTALLATION OF A CONDENSATE

NEUTRALIZER AND PUMP

(

Not Supplied

)

Installation

At a minimum, use 1 1/2" pipe for GHE119/125-500

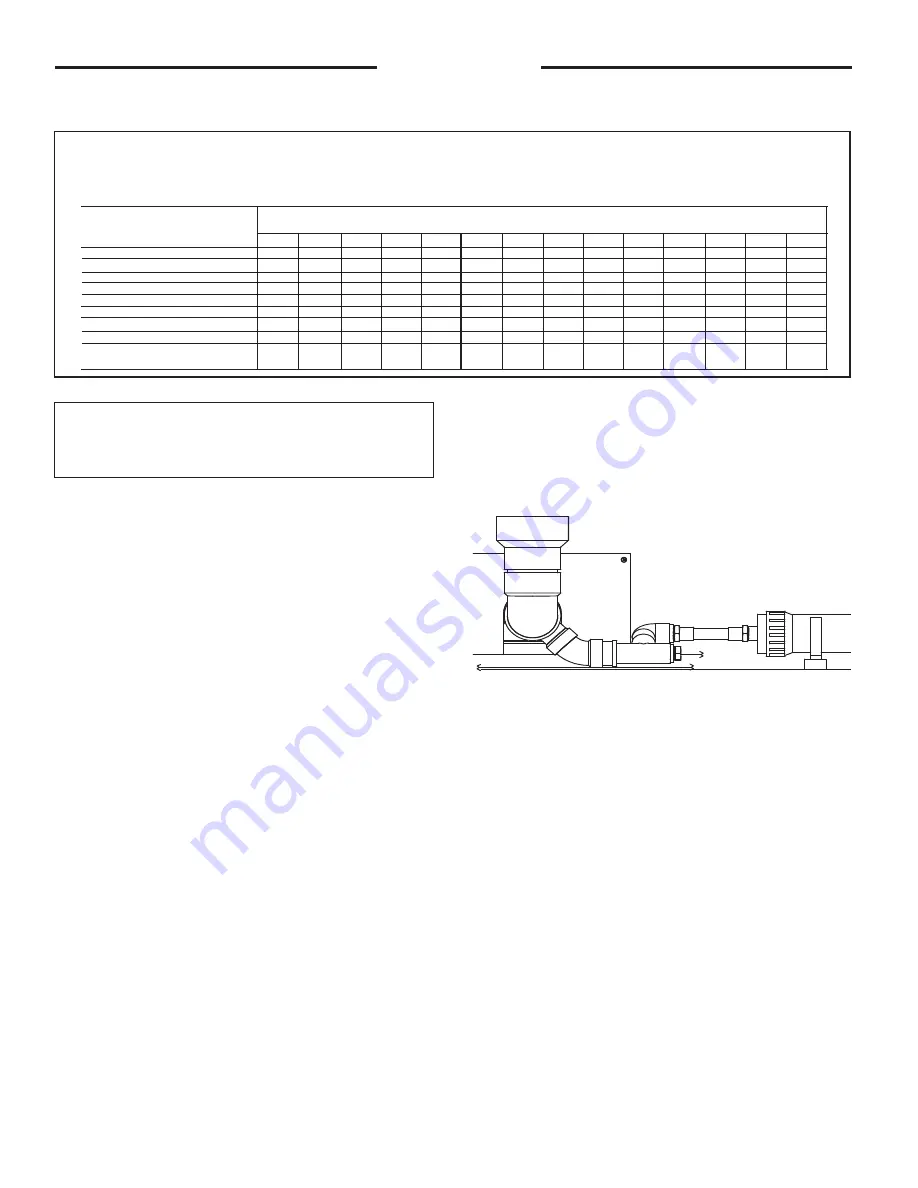

TABLE 3

For U.S. Installations

Maximum Capacity of Pipe in Cubic Feet of Gas per Hour for Gas Pressures of

0.5 psig or Less and a Pressure Drop of 0.3 Inch Water Column

Based on a 0.60 Specific Gravity Natural Gas; If 1.5 Specific Gravity L.P. Gas is used, multiply capacity by 0.63

Nominal Internal

Iron Pipe Size

Diameter

Inches Inches

10

20 30 40 50 60 70 80 90 100 125 150 175 200

1/2

.622

132 92 73 63 56 50 46 43 40 38 34 31 28 26

3/4

.824

278 190 152 130 115 105 96 90 84 79 72 64 59 55

1

1.049

520 350 285 245 215 195 180 170 160 150 130 120 110 100

1

1/4

1.380

1,050 730 590 500 440 400 370 350 320 305 275 250 225 210

1

1/2

1.610

1,600

1,100 890 760 670 610 560 530 490 460 410 380 350 320

2

2.067

3,050 2,100 1,650 1,450 1,270 1,150 1,050 990 930

870 780 710 650 610

2

1/2

2.469

4,800 3,300 2,700 2,300 2,000 1,850 1,700 1,600 1,500 1,400 1,250 1,130 1,050 980

3

3.068

8,500 5,900 4,700 4,100 3,600 3,250 3,000 2,800 2,600 2,500 2,200 2,000 1,850 1,700

4

4.026

17,500 12,000 9,700 8,300 7,400 6,800 6,200 5,800 5,400 5,100 4,500 4,100 3,800 3,500

Length of Pipe, Feet

Maximum Pipe Capacity for Installations in Canada,

refer to CAN/CSA B149.1.

For Natural Gas see Tables A.1 to A.17

For Propane (LP) Gas see Tables B.1 to B..12

Figure: 2

Содержание GHE 125-500A

Страница 20: ...20 Installation Schematic Diagram Figure 18...

Страница 25: ...25 Operation Steps to adjust the setpoint temperature Figure 21...

Страница 37: ...37 Notes...

Страница 38: ...38 Notes...

Страница 39: ...39 Notes...