11.0 Maintenance

and Service

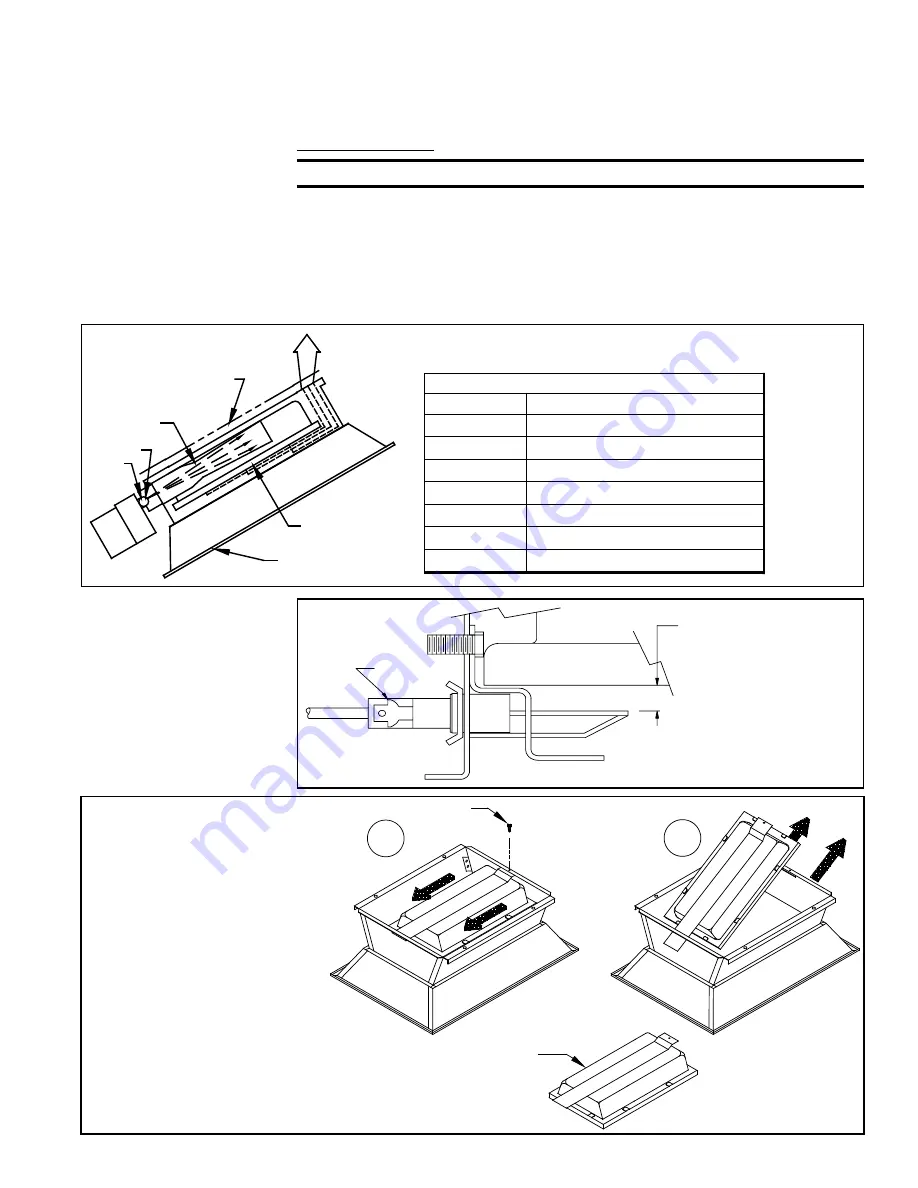

FIGURE 9 - Electrode

Assembly (Direct

Spark)

Electrode

Burner

Proper installation

results in 0.219 ± 0.032”

(5.6mm) clearance

from ceramic tile surface

to the sparking tips of

the electrode.

Refer to the illustrations below.

• FIGURE 8

illustrates general arrangement of heater operation.

• FIGURE 9

shows the direct spark assembly.

• FIGURE 10

illustrates burner removal.

Annual maintenance

should be performed as follows:

CAUTION: Always wear protective goggles when cleaning heaters.

1.

Disconnect all power sources related to the installation and close the gas supply

valve at the heater.

2.

With an air hose of 20 PSI (140kPa) or less, blow off all accumulated dust and dirt.

Blow air over the ceramic tile (avoiding gasket material between tile) and

alternately into the venturi several times in succession. Be careful not to damage

gasket material between ceramic tiles. Damaging the material between the tiles

could lead to burner flashback.

E

D

C

B

A

G

F

LEGEND

Symbol

Item Description

A

Gas manifold

B

Gas orifice

C

Venturi

D

Optional heat deflector

E

Heater flue exhaust path

F

Ceramic tile surface

G

Standard reflector assembly

FIGURE 8 - General Arrangement

1

2

Screw

Ceramic Tile

Burner Assembly

(removed)

FIGURE 10 - Burner

Replacement

Burner Removal

Instructions

1)

Remove screw and slide

burner backward.

2)

Pull burner up and

outward.

Reverse the procedure to

re-install burner.

11.1 Maintenance

Procedures and

Illustrations

Form I-RIH, P/N 131793R8, Page 17