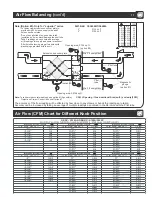

5. Published efficiencies are based on balanced air-flows

on supply and exhaust.

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

www.reversomatic.com • [email protected]

WARNING

!

!

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK

OR INJURY, OBSERVE THE FOLLOWING:

1. Read all the instructions carefully before installation,

operation or maintenance of the unit. Failure to comply

with instructions could result in personal injury and/or

property damage.

2. Installation of the unit and the corresponding electrical

wiring must be done by a qualified person and be in

accordance with all municipal and national electrical

codes and pertinent industry standards should be

verified before installation.

3. Use this unit only in the manner intended by the

manufacturer. If you have any questions, contact the

manufacturer.

4. Moving Parts, Disconnect Power supply before opening.

ensure that all the nuts and screws are securely

fastened before restarting the unit.

5. Before servicing or cleaning the unit, switch power off at

service panel and lock the service disconnecting means

to prevent power from being switched on accidentally.

When the service disconnecting means cannot be

locked, securely fasten a prominent warning device,

such as a tag, to the service panel.

6. When cutting or drilling into wall or ceiling, make sure

that you do not damage electrical wiring and other

hidden utilities.

7. To reduce the risk of fire, use only metal ductwork.

Do not use any accessories not recommended by the

manufacturer.

8. When performing installation, servicing or cleaning

these unit, it is suggested to wear safety glasses and

gloves.

9. Do not use this unit for commercial purpose.

10. For residential use only. The unit must be grounded.

11. Do not install in a cooking area.

12. This unit is not designed to exhaust combustion and/or

dilution air for fuel burning appliances.

CAUTION

!

!

1. Turn the unit OFF during construction or repair to avoid

filter blockage.

2. Exhaust air outside - Do not intake / exhaust air into

spaces within walls, crawl spaces, garage, or into attics.

3. Unit has to be installed in accordance to National and

Local Building Code.

4. When leaving house for a long period of time (more than

two weeks), a responsible person should check if unit

operates adequately.

PACKAGING INSPECTION

Open the box and check to make sure all the parts and

accessories are present and in good condition. If you find

any parts missing or any shipping damage please contact

factory or our distributor immediately.

Parts List

• Superior Series

(RHRV-S100A, RHRV-S100P, RERV-S100)

• Project Series

(RHRV-P100A, RHRV-P100P, RERV-P100)

• Economy Series

(RHRV-E100A, RHRV-E100P, RERV-E100)

• Maxum Series

(RHRV-S200A, RHRV-S200P, RERV-S200)

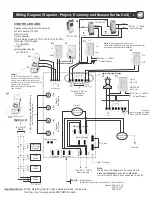

Wiring Diagram

• Superior and Project Series

• Furnace / Fan-Coil / Heat Pump Interlock

- Standard Furnace Interlock Wiring

- Alternate Furnace Interlock Wiring

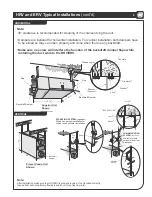

HRV and ERV Typical Installations

• For Houses

- Fully Ducted System

- Furnace Return Air-duct connection

- Semi Ducted System

•

For High Rise Condominium

- Fully Ducted System

- With Fan-Coil System

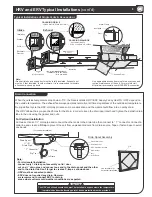

• Horizontal

• Vertical

• Access Door Installation

• Drain Connection

Air Flow Balancing

• Balancing Procedure

• Pitot Tube Air Flow Balancing

Maintenance

• Regular Maintenance

• Annual Maintenance

Troubleshooting

Climate Zone

1

2

3

4

5

6

7

7

8

8

9

9

10

10

11

12

12

14

CONTENTS