Operation and Maintenance Manual – Steam sterilizers mod. Full Clave

Rev. 01 of 01-12-2006 - C:\Documenti\Manuali di istruzione\FULL CLAVE GB-R01.doc

Page 20 of 34

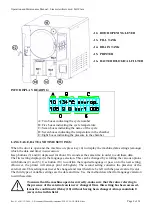

8.2 Troubleshooting: Solutions/Remedies

Message displayed

Causes

Remedies

Pressure leaks from the

door.

Check the door seal. Replace it if it is

damaged or caked, then adjust the door

pressure (see page 21).

Defective N.O. solenoid

valve.

Clean or replace the solenoid valves.

Defective 3-way N.C.

solenoid valve.

Worn vacuum pump

seals.

Replace the pump seals.

Vacuum pump blocked.

Check operation and/or replace the pump.

INSUFFICIENT VACUUM,

INSUFFICIENT

FRACTIONED VACUUM

Burnt-out fuse on power

board.

Replace fuse on power board.

Air in the chamber.

Add a vacuum peak if cycle number 9

(“special”) has been chosen.

The temperature probe

hits against an object in

the chamber.

Make sure that the temperature probe does not

strike against objects in the chamber.

Sterilizing load with too

many fabrics.

Reduce the load of fabrics.

OVERTEMPERATURE

ALARM,

HEATING ALARM,

Defective transducer.

Open the door and check whether the

atmospheric pressure appears on the display (~

1 bar). Replace the transducer if the value is

very different.

Water fill tank empty.

Fill the fill tank.

WATER LEVEL TOO

LOW

Level probe defective or dirty.

Clean the fill tank, check and clean the

tank level probes (for the technician

only).

USED WATER TANK FULL

Used water tank full.

Empty and rinse the used water tanks.

Steam outlet N.C. solenoid

valve defective.

Replace the N.C. solenoid valve.

Generator heating elements

defective.

Check the heating elements and replace

them if necessary.

The safety thermostat has

activated.

Reset the thermostat in manual mode

and identify the cause of the

overtemperature.

PRESSURIZING ALARM

Pressure switch with

incorrect setting or

defective.

Correctly set (at 3 bar) or replace the

pressure switch.

Water feed pump defective.

Check the fill pump and replace it if

necessary.

Water inlet filter clogged.

Replace the inlet filter.

INSUFFICIENT

STEAM

Water level probe defective.

Check with a tester and replace if

necessary.