29

29

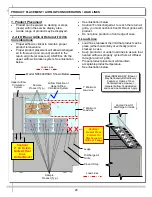

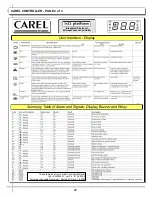

Summary Table of Operating Parameters

CAREL CONTROLLER - PAGE 3 of 3

Integrated Electronic

Microprocessor Controller

CODE

PARAMETER

UOM* TYPE MINIMUM MAXIMUM

DEFAULT

/5

Select Celsius (°C) or Fahrenheit (°F)

flag

C

0

1

/c1

Calibration of probe 1

°C/°F

C

-20

20

/c2

Calibration of probe 2

°C/°F

C

-20

20

St

Temperature set point

°C/°F

F

r2

r1

rd

Control delta

°C/°F

F

20

0.1

dl

Interval between defrosts

hours

F

0

250

d4

Defrost activated when instrument is

switched on**

-

-

0

1

dt1

End defrost temperature, evaporator

°C/°F

F

-50

200

dP1

Maximum defrost duration, evaporator

min

F

1

250

d6

Display on hold during defrost

-

C

0

2

dd

Dripping time after defrost

min

F

0

15

d/1

Display of defrost probe 1

°C/°F

F

-

-

For Case

Specific

Defaults

See Serial

Label

Located

Near

Electrical

Access

On Your

Case.

For

Additional

Technical

Information

Call

Structural

Concepts

Technical

Service

Dept. at

1(800)

433.9490

Ext. 1

* Unit Of Measure

This data derived from Carel® Controller Material:

ir33 +030220441 - rel. 2.0 - 01.05.2006.

Structural Concepts Document - Revision C Date: 1.4.2022

** Case will go into defrost ONLY when case is turned off and then

back on when probe is reading below 45 °F.