XL80 laser system

65

www.renishaw.com/xl80

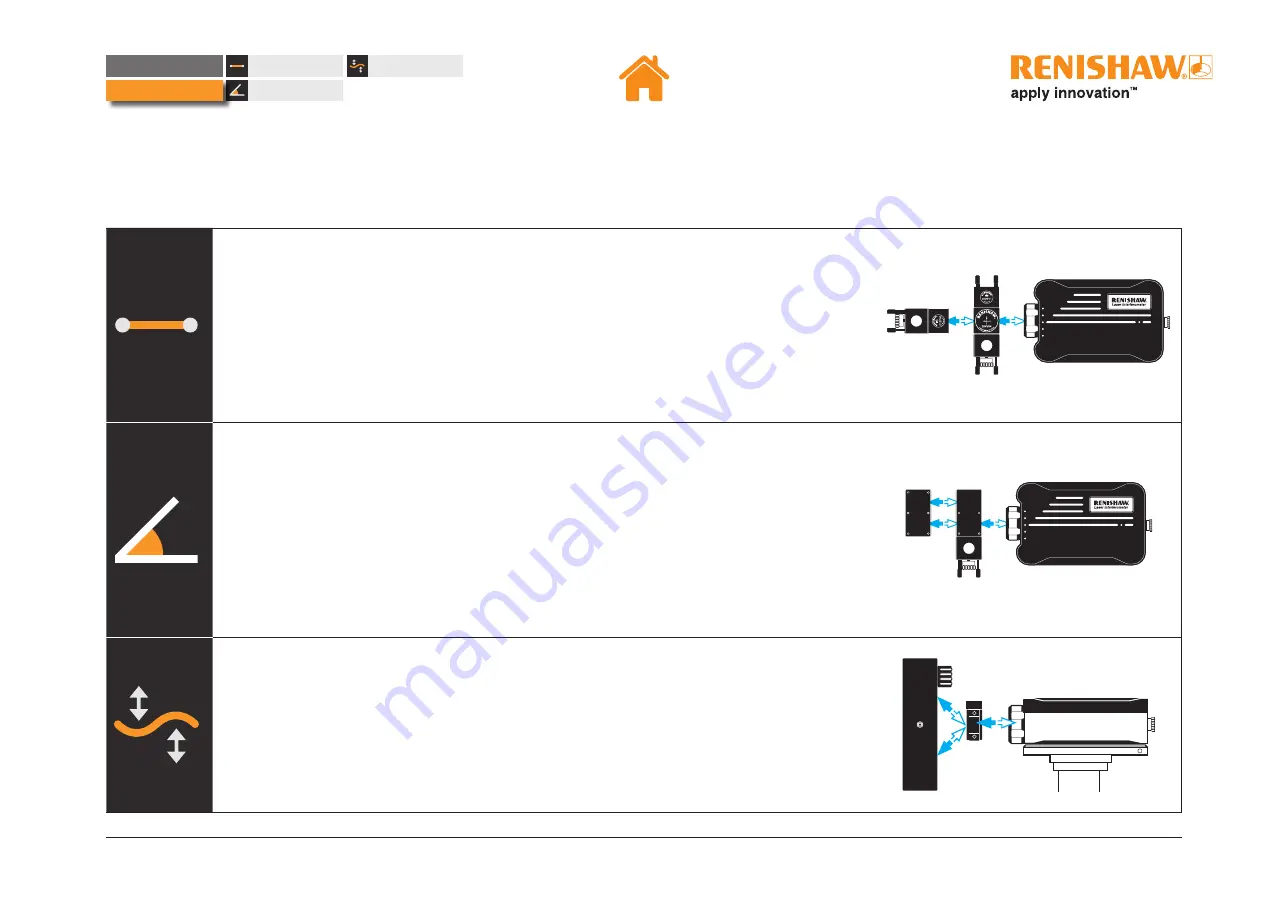

Linear

Linear measurement is the most common measurement mode performed with a laser�

Any inaccuracy from the commanded position in a position critical motion system is often caused

by factors such as changes in environmental conditions, mechanical wear, or angular pitch and

yaw. Accuracy and repeatability are measured by driving to a series of pre-defined positions

controlled by the motion system readout� At each position, a reading is then taken using the

laser� The error is the difference between the controller readout and the laser readout�

MA

DE IN UK

Angular

Angular errors are often one of the biggest contributing factors to linear positioning errors�

Angular errors are often caused by a bow in the motion of travel (pitch angle error) or slack

guide leading to a rotation of the drive carriage (yaw angle error)� The measurement technique

is similar to that of linear measurement with readings being taken at a series of pre-defined

positions to measure the angular change along the linear axis to ensure that the point of interest

is in its correct linear position� Pitch and yaw errors are measured independently with the angular

optics in different orientations�

Straightness

Straightness measurements are often a consequence of a vertical or horizontal deviation which

is perpendicular to the axis of travel in a drive system or overall misalignment of guide rails�

The error is a vertical or horizontal deviation which is perpendicular to that of the motion of travel�

Straightness errors are often caused by wear in the guide rails, an impact along the axis, or poor

assembly of the drive carriage�

Introduction

Measurement modes

This guide includes:

Содержание XL-80

Страница 1: ...renishaw www renishaw com xl80 XL 80 laser system...

Страница 10: ...renishaw XL 80 hardware...

Страница 63: ...renishaw XL 80 applications...