RGH40 RESR

installation guide

7

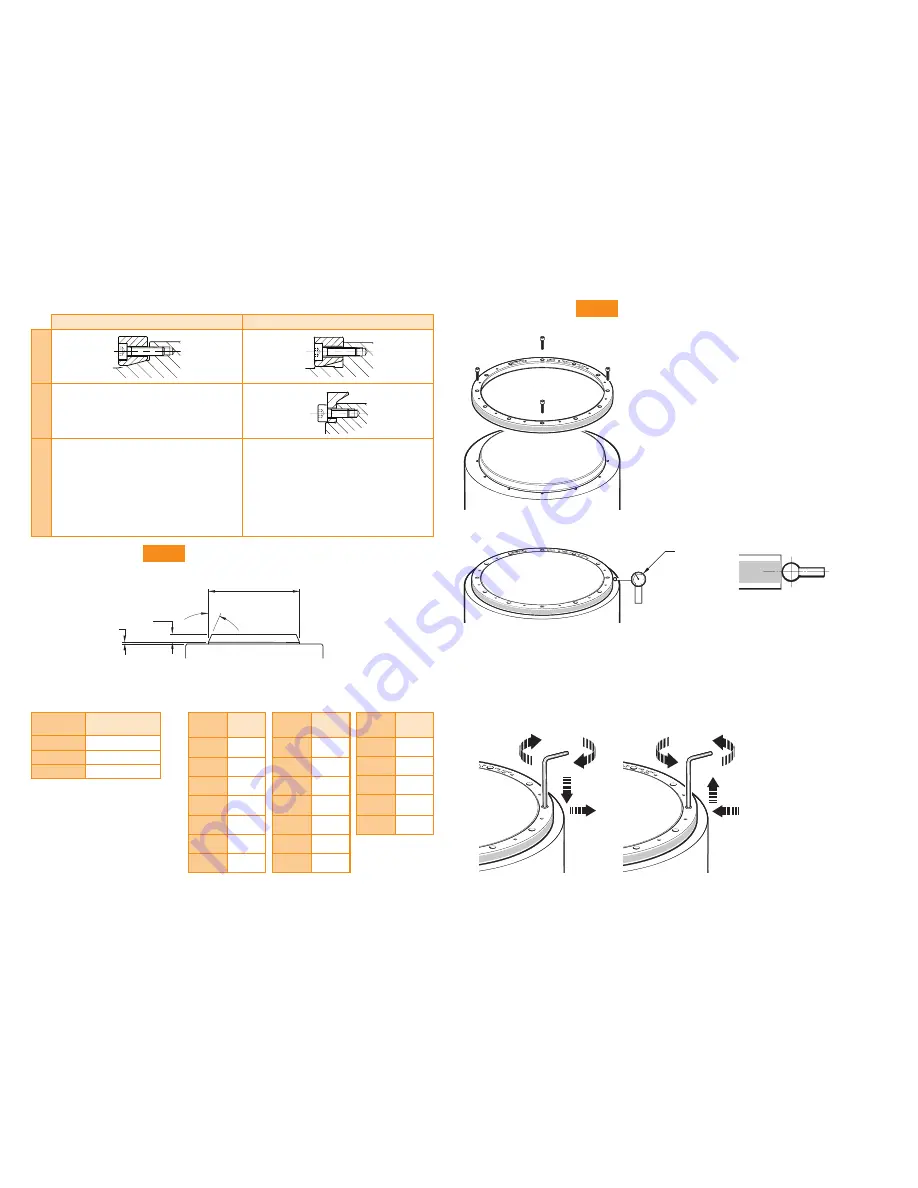

Select a mounting option

Taper mount

Interference fit

‘A’

section

‘B’

section

Not applicable

Notes

Recommended for all installations

Enables simplest adjustment

Offers highest accuracy

Enables eccentricity to be compensated

Offers excellent mechanical stability against

thermal cycling, shock and vibration.

Minimises cost of substrate preparation

Alternative installation

Will not correct eccentricity of the

supporting shaft

Recommended taper roundness

Recommended surface finish

≤

Ra 1.2

NOTE:

It is recommended that

the mounting surface is a turned,

rather than ground finish.

DO = Nominal external diameter

Recommended taper diameter (

DT

)

Step 2

Taper mount method

u

Clean shaft taper and internal taper of RESR as

recommended in the storage and handling section.

u

Insert the first screws:

For RESR rings with 6, 9 or 18 mounting holes,

use 3 equally spaced M3 screws.

For RESR rings with 12, 16 or 20 mounting holes,

use 4 equally spaced M3 screws.

NOTE:

Do not lubricate screws.

Recommended screw type M3 × 0.5:

ISO 4762/DIN 912 grade 10.9 minimum/ANSI B18.3.1M.

u

Insert the screws so that the RESR is loosely connected to

the shaft, then roughly align the ring by eye and touch.

u

Lightly tighten the screws. Use a Dial Test Indicator (DTI)

to check the radial displacement at the screw locations.

NOTE:

Disregard the radial displacement between the

screw locations.

u

Adjust the screws to reduce the range of radial displacement. When adjusting, identify the screw location

with the lowest radial displacement and tighten that screw, aiming for the average of the highest and lowest

indicator readings.

u

Repeat this process until the DTI readings are within ±5 µm at the screw locations.

NOTE:

It may be necessary to loosen screws whilst tightening other screws.

DTI

Use a DTI with low exertion force to avoid scratching the

scale surface. A DTI with a ruby ball stylus is recommended

as a further precaution against scratches.

NOTE

: At this stage, the screws

should only be lightly tightened

(less than 0.5 Nm)

to allow further final adjustment.

*

Allow 2 mm for 417 mm, 489 mm and 550 mm rings only

15° ±0.2°

DT

7 min

1

*

Step 1

Taper mount method

Mounting shaft specifications

Diameter

(mm)

Roundness value

(mm TIR)

≤

115

0.025

150 to 255

0.050

≥

300

0.075

DO

(mm)

DT

(mm)

52

33.85

33.65

57

40.85

40.65

75

58.85

58.65

100

83.85

83.65

103

83.85

83.65

104

83.85

83.65

115

98.85

98.65

DO

(mm)

DT

(mm)

150

133.85

133.65

200

183.85

183.65

206

189.85

189.65

209

189.85

189.65

229

212.85

212.65

255

238.85

238.65

300

283.85

283.65

DO

(mm)

DT

(mm)

350

333.85

333.65

413

395.85

395.65

417

383.85

383.65

489

454.85

454.65

550

513.85

513.65