7

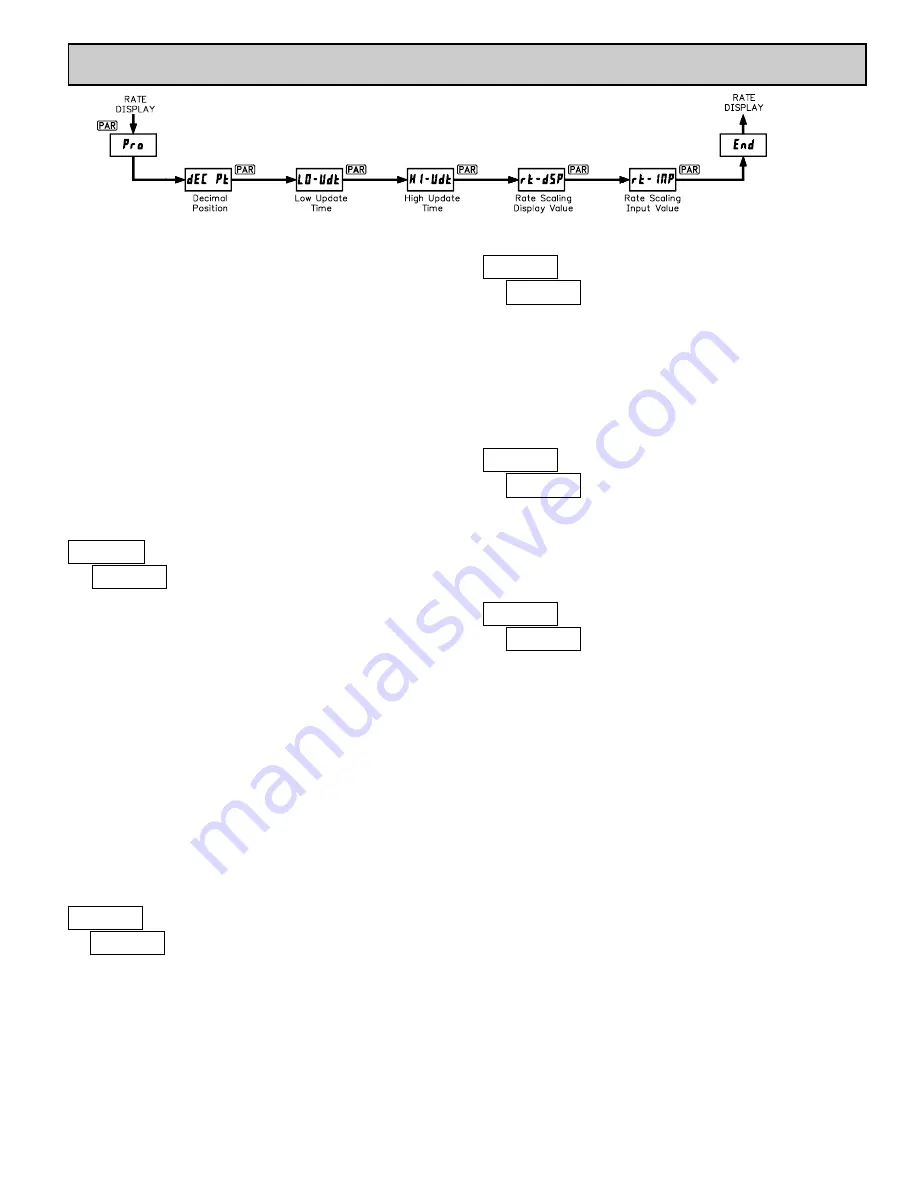

The Rate Indicator has five programmable parameters which are entered in

the sequence shown above, using the front panel push buttons.

Before programming, refer to the section on Scaling the Meter to determine

the Rate Scaling Display Value and Rate Scaling Input Value to use for the

specific application.

Note: Programming mode can be locked out with the Program Disable DIP

switch. With the switch in the Disabled (up) position the meter will not enter

programming mode. Refer to the section on DIP switch setup.

PROGRAMMING MODE ENTRY

Press the

PAR

key to enter Programming Mode. The meter briefly displays

#$%

followed by the first programming parameter described below.

PROGRAMMING PARAMETERS

In programming mode, the display alternates between the parameter and the

current selection or value for that parameter. The dual display with arrows is

used below to illustrate the alternating display. The selection choices or value

range for each parameter is shown to the right of the alternating display.

This parameter selects the decimal point position on the display. The

selection does not affect scaling calculations.

Press the arrow keys (

"

or

!

) to sequence through the selection list until the

desired selection is shown. Press the

PAR

key to save the displayed selection

and advance to the next parameter.

ENTERING NUMERICAL VALUES

The parameters which follow are displayed as a multi-digit numerical values

with one selected digit flashing (initially the far left digit). Press the

"

(up

arrow) key to increment the value of the selected (flashing) digit. Holding the

"

key automatically scrolls the value of the selected digit.

Press the

!

(down arrow) key to select the next digit position to the right.

Use the

"

key to increment the value of this digit to the desired number. Press

the

!

key again to select the next digit to be changed. Holding the

!

key

automatically scrolls through each digit position.

Repeat the “select and set” sequence until all digits are displaying the desired

numerical value. Press the

PAR

key to save the displayed value and advance to

the next parameter.

The Low Update Time is the minimum amount of time between display

updates. The factory setting of 1.0 allows a minimum of one second between

updates. Low values below 0.3 seconds will update the display correctly, but

may cause the display to appear unsteady.

For more details on display updating, refer to Input Frequency Calculation.

The High Update Time is the maximum amount of time before the display is

forced to zero. The High Update Time

must

be higher than the Low Update

Time and also higher than the desired slowest readable speed (one divided by

pulses per second). The factory setting of 2.0 will force the display to zero for

speeds below 0.5 Hz or one pulse every 2 seconds.

For more details on display updating, refer to Input Frequency Calculation.

Enter the desired Rate Display value to be shown for the corresponding Rate

Input value entered below. For more explanation, refer to Rate Scaling.

If a decimal point was selected in the Decimal Position (

&'( #*

) parameter,

it will be displayed at the same position for this parameter value.

Enter the Rate Input value that corresponds to the Rate Display value entered

above. This value is always in pulses per second (Hz). For more explanation,

refer to Rate Scaling.

PROGRAMMING MODE EXIT

The meter exits Programming Mode when the

PAR

key is pressed to save the

Rate Scaling Input Value. The meter briefly displays

'+&

upon exiting

Programming Mode. All programmed selections are now transferred to the non-

volatile memory and the meter returns to the Rate display.

(If power loss occurs during programming mode, verify parameter changes

and reprogram, if necessary, when power is restored.)

PROGRAMMING MODE TIME OUT

The Programming Mode has an automatic time out feature. If no keypad

activity is detected for approximately 60 seconds, the meter automatically exits

Programming Mode. The meter briefly displays

'+&

and returns to the Rate

display. When automatic timeout occurs, any changes that were made to the

parameter currently being programmed, will not be saved.

FACTORY SETTINGS

The factory settings for the programming parameters are shown above in the

alternating display illustrations. The factory settings can be easily restored by

removing power from the meter, and then pressing and holding the

PAR

key

while power is reapplied. The meter displays

$','*

until the

PAR

key is

released. The normal power-up sequence then resumes, with the factory settings

loaded and saved in non-volatile memory.

Note: The Program Disable DIP switch must be in the Enabled (down)

position to allow loading factory settings. See section on DIP switch setup.

"

#

)

&'( #*

"

#

*+)

,-#.$"

)+*

to

00+0

seconds

DECIMAL POSITION

LOW UPDATE TIME (DISPLAY UPDATE)

)+)))))

)+))

)+))))

)+)

)+)))

)

"

#

1+)

2'#.$"

)+1

to

00+0

seconds

HIGH UPDATE TIME (DISPLAY ZERO)

"

#

*)))

!"#$%&

)

to

000000

RATE SCALING DISPLAY VALUE

"

#

*)))+)

!"#'(&

)

to

00000+0

RATE SCALING INPUT VALUE

6.0 P

ROGRAMMING THE

M

ETER

PROGRAMMING SEQUENCE