19

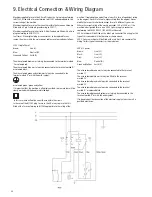

6. Operation & Planer Thicknesser Practice

- cont.

6.4 Planing

Fix the extraction port in position as shown in

Section

6.1

.

This operation is carried out for straightening

a workpiece and for trimming the long side of

panels. Place workpiece flush on to in-feed table,

with your left hand set the cutter guard to the

required height (workpiece should be run clear

of the guard). Start the machine and push timber

slowly and steadily against the cutterblock,

moving hands over the cutter guard as the

timber is pushed under it, see

Fig.6.5A

.

The depth of cut can be altered by setting the

infeed table to line up with the marking on the

scale. The top line is zero and the bottom line is

a 3 mm cut. It is not advised to take the deepest

cut, a shallow cut will give better results and put

less strain on the machine

Fig.6.5B

.

To increase the depth of cut simply rotate the

infeed adjustment knob anti clockwise

Fig.6.5C

.

6.5 Jointing

For planing the narrow sides of a workpiece,

release the cutter guard's lock lever and set the

cutter guard to the width of the workpiece. The

spring on the end of the cutter guard should

exert a slight pressure against the workpiece.

Lock blade guard in place and start the machine.

Push workpiece slowly and steadily against

cutter block. Ensure that fence is set at the

required angle and the workpiece is kept flush

against the fence

Fig.6.6

.

This gives you 2 datum surfaces; explanation

below

Fig.6.7A

.

After straightening

side 1

, turn the workpiece

90º so that

side 1

now lines up along the fence.

Surface

side 2

at 90° in order to carry out

thicknessing: this way it is possible to obtain a

finished piece planed on all 4 sides.

When

side 1

is positioned flat against the

thicknessing bed,

side 3

is cut exactly square

Fig.6.7B

. Likewise when

side 2

is positioned

flat against the thicknessing bed,

side 4

is cut

square the end result is a completely square

piece of timber

Fig.6.7C

.

Before proceeding with thicknessing, carefully

read the advice on safety and planer-protection

adjustment on the following pages.

Fig.6.5A

Fig.6.6

Fig.6.5B

Depth Scale

Fig.6.5C

Adjustment Knob

90º

Fig.6.7A

Thicknessing

bed

1

3

2

Fig.6.7B

Cutterblock

Thicknessing

bed

2

1

4

3

Fig.6.7C

Side 1

Fence

Surface

planing table

Surface

planing table

Side 1

Side 2

Side 1

Side 3

Side 2

Side 4

Side 1

Side 3

Side 4

Side 2

Plastic spring

Содержание PT260

Страница 28: ...28 11 Parts Diagrams Stand Wheel Kit ...

Страница 29: ...29 11 Parts Diagrams cont ...

Страница 30: ...30 11 Parts Diagrams cont ...

Страница 34: ...34 ...

Страница 35: ...35 ...