28

FUTERA II INSTALLATION AND OPERATION INSTRUCTIONS

3. When fi re tested at the factory the unit’s input was

rated and the gas pressure(s) recorded on the test

label affi xed to the jacket next to the junction box. To

confi rm the input of the unit follow the instructions in

the INPUT RATE section below. The gas pressure

setting(s) for dual fuel units may vary; refer to the test

label on the unit.

4. An undiluted fl ue gas sample must be taken at the

fl ue outlet using a calibrated fl ue gas analyzer. Allow

the unit to run for 15 minutes before taking

the sample. For a natural gas unit the low fi re CO

2

reading should be 7.3%-7.5% and 8.5%-8.8%

for propane gas. The high fi re CO

2

reading should be

7.5%-8.0% and 8.8%-9.4% for propane gas.

Exceeding 8.0% on natural gas or 9.4% on propane

gas CO

2

will shorten the life of the burner. Adjust the

inlet air damper to achieve the correct CO

2

readings.

5. If the pressure settings vary from those listed in Table

8, please affi x a new label or notice to the boiler, which

shows these new settings. However, do not sacrifi ce

or compromise safe combustion, carbon monoxide

limits, or safety settings to achieve these fi gures. The

pressures listed in Table 8 are guidelines obtainable

under ideal conditions.

6. To test the ignition safety shutoff device, close the

manual shutoff valve in the gas supply line. Within 5

seconds of main burner fl ame extinction, the main gas

valve solenoid should close with an audible noise. After

15 seconds the module should lockout and the trial for

ignition end. After 5 minutes a second trial for ignition

should occur. Open the manual shutoff valve in the gas

supply line and reset the ignition control system. A

normal ignition sequence should take place. If the

burner hasn’t lit after the last ignition try, the gas valve

will close and the system will go into lock out only on

CSD-1 units otherwise, the boiler will retry every 5

minutes. Inspect the ignition system to determine what

the problem is.

7. With the main burner in operation, close the manual

fi ring valve. As soon as the main burner fl ames go out,

open the manual firing valve. A normal ignition

sequence should take place. If the burner fails to light

the system will make one more ignition attempt.

8. With the burners in operation, interrupt the power to

the control circuit by lowering the operating control or

thermostat. The main burners should go out. Reset the

operating control or thermostat, a normal ignition

sequence should follow.

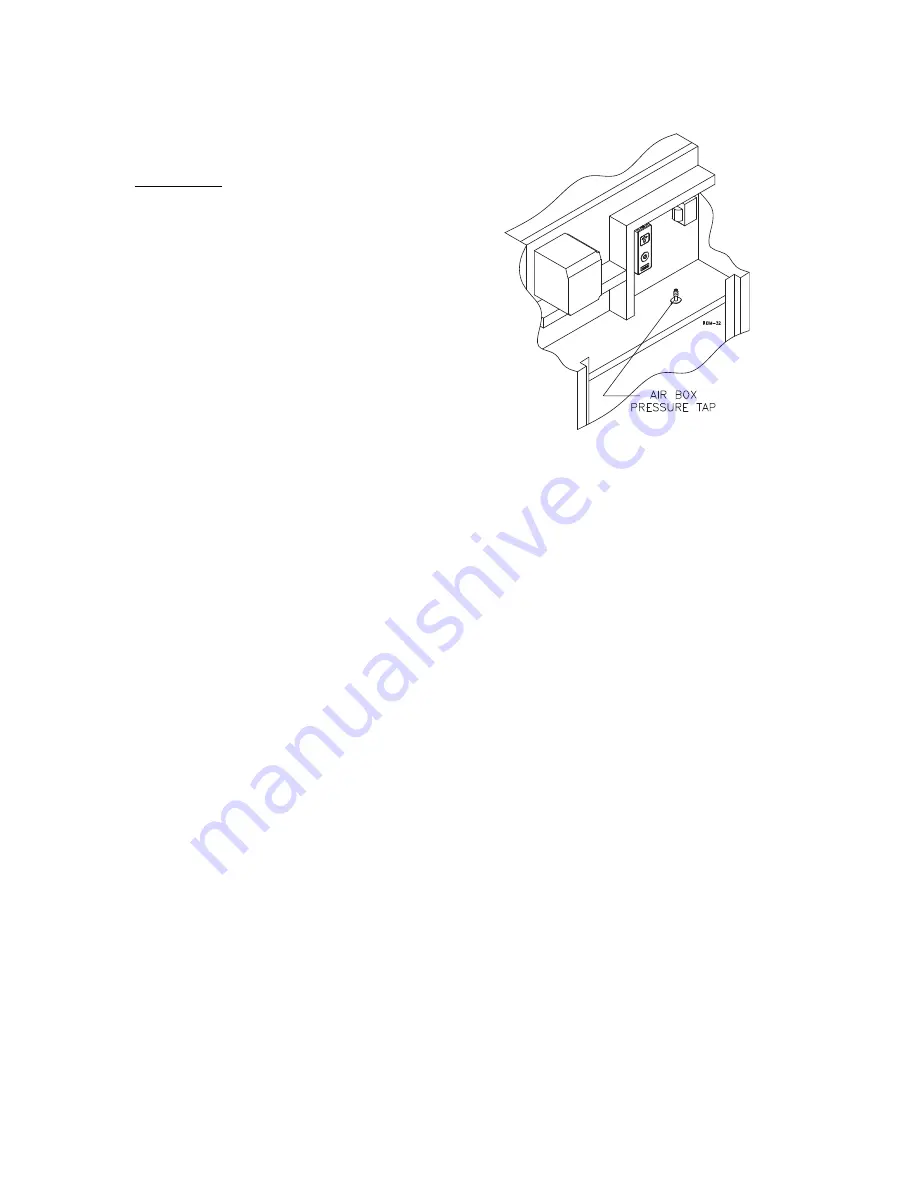

Air Box Pressure

Connect a manometer to the air box pressure tap located

behind the control cover, Figure 21.

Table 9 lists the factory settings for the air box pressure

and gas back pressure that were set using a minimum

length of vent pipe. It may be necessary to adjust the air

shutter on the blower to achieve acceptable combustion

readings for certain installations.

Figure 21 – Air Box Pressure Tap

If vented vertically ensure that the barometric damper is

capable of maintaining the air box pressure listed in Table

9. An air box pressure lower that that listed in Table 9 can

signifi cantly reduce the life of the burner.

Long horizontal vents will result in an air box pressure

higher that that listed in Table 9. It may be necessary to

open the air damper to obtain the correct combustion

settings.

Required Gas Pressure

Connect a manometer to the gas pressure test port

upstream of the fi ring valve, Figure 22. Close the manual

shut off valve for the pilot gas. Ensure that the fi ring valve

is in the open position. Energize the unit and allow it to try

for ignition until it goes into fl ame failure. If the gas back

pressure is signifi cantly different from that listed in Table 9

the air/gas mixing tube may be misaligned.

Provide gas supply pressure at inlet to boiler gas train as

follows:

LP

Nat

Minimum (in W.C.)

11

5

Maximum (in W.C.)

14

14

Measure pressure when the boiler is fi ring at full rate. Low

gas pressure could indicate undersized gas line or

insuffi cient gas supply.