RG13II Operation • Maintenance • Parts

800.392.2686

31

Maintenance

remove a clear “kerf” from the stump without the body

of the tooth ever contacting the stump. This concept

reduces drag, which maximizes the use of the machine’s

horsepower. This also reduces wear on the tooth body

and on the attachment hardware. Many of the other

cutting tool systems available today do not address this

important aspect of cutting.

• Cutting Tool Dimensions: Rayco’s stump cutting teeth

are carefully designed to have the proper size of carbide

tip. Carbide tips ultimately become dull, and using

large, oversized carbide tips will induce extreme impact

energies into the machine’s structure.

• Debris Retention: Rayco’s cutting tool patterns are

designed to minimize the retention of debris in between

the cutting tools. This debris can cause imbalance. This

debris can also become a dangerous projectile. Non-

Rayco cutting tools may retain more debris.

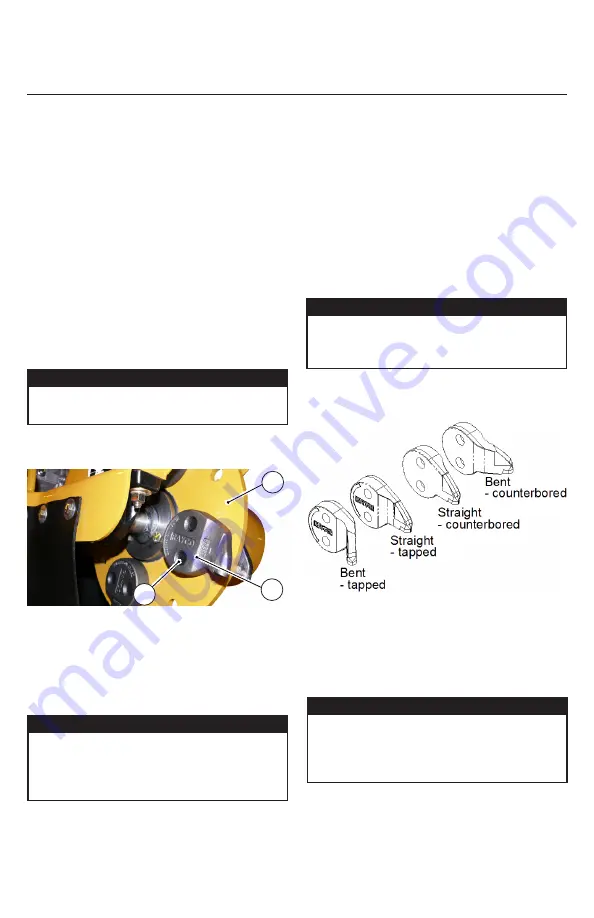

Changing Teeth

Support the cutter wheel in a raised position when

changing teeth.

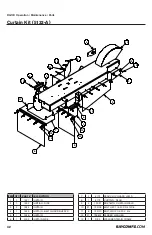

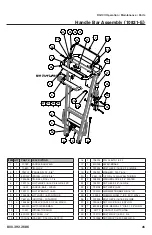

1) Clean all dirt from the cutting wheel (2) and teeth (3).

2) Remove the socket head bolts (4) from the teeth (3).

(The 1/2” hex key provided with the machine may be

used.)

3) Check the cutting wheel for cracks. Replace the wheel

if it is cracked.

4) Carefully select and properly position each tooth

according to diagrams.

5) Position teeth as shown in the diagram in the Parts

manual. Straight and angled teeth should be staggered

as shown in the drawing.

6) When using Rayco brand square-shanked teeth, set

the extreme edge of each tooth 1¼” away from the

edge of the pocket.

7) When using Rayco SUPERTEETH, because of one piece

construction, no pre-setting of the tooth is required.

8) Make sure teeth are placed in coordination with wheel

rotation.

9) After setting each tooth pair, tighten the socket head

bolts to 135 to 145 foot-pounds.

Replacement teeth and pockets are available from your Rayco

dealer or direct from Rayco. Refer to the Parts manual for

part numbers.

There are four types of Superteeth, as shown in the above

diagram. The counter bored teeth are on one side of the cutting

wheel, the tapped teeth on the opposite side. The tips of the

bent teeth will always point away from the cutting wheel.

Sharpening Teeth

Do not allow any tooth to wear too much before sharpening.

Discard any tooth that has lost more than 1/8” of original bite.

The teeth must be removed from the cutting wheel for proper

sharpening.

NOTICE

Read all of the following instructions before

beginning to change cutting wheel teeth.

NOTICE

The drawing in the Parts manual represents the

exact location required for positioning each tooth.

When followed exactly, optimum cutting wheel

performance is attained.

NOTICE

Do not hammer the tip of a tooth. Due to the super

hardness of the tooth, it is brittle and may chip from

such treatment.

NOTICE

Sharpening cemented carbide cutting teeth requires

a special process. Have your teeth sharpened only

by a qualified machinist for obtaining a proper edge

and to avoid injury.

2

3

4