21

Where the flue passes through a combustible material, a twin

wall solid packed insulated chimney connector must be used

and must come flush with the outer surface of the material

and run all the way to the masonry chimney or to the point of

termination of the factory made chimney.

(You should discuss the installation of your Rayburn cooker

with your builder in this regard in the case of a newly fitted

kitchen.

When installing a non-combustible worktop, it is necessary to

allow adequate clearance for the removal of the hob.

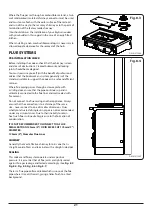

FLUE SYSTEMS

PRE-INSTALLATION CHECK

Before installing the cooker, check that the chimney is clean

and clear of obstructions. Cracked brickwork and leaking

joints should be made good.

You must reassure yourself (with the benefit of professional

advice) that the brickwork and system generally is of the

standard suitable to support the cooker in a safe and efficient

manner.

Where flue piping passes through a closure plate with

a sliding door, ensure that the pipe continues up and is

ultimately connected to the flue liner and well-sealed with

fire cement.

Do not connect to a flue serving another appliance. Always

ensure that the connection is to a chimney of the same

size - never connect to one of smaller dimensions. Flues

wholly constructed of single skin pipe are not recommended

under any circumstances. Due to their inability to retain

heat such flues will inevitably give rise to the formation of

condensation.

IT IS NOT RECOMMENDED TO CONNECT TO A FLUE

SMALLER THAN 125mm (5”) OR IN EXCESS OF 175mm (7”)

DIAMETER.

125mm (5”) Diameter Flue Liner

CHIMNEY

Generally the most effective chimney for oil is one that is

straight, avoid offsets and terminate with a straight sided pot.

SEALING

This cooker and flue system operate under a positive

pressure. It is essential that all flue joints are tightly sealed

against flue gas leakage and tested accordingly. (See

There is a flue pipe collar available which surrounds the flue

pipe where it meets the wall, giving a tidier finish to a tiled

background.

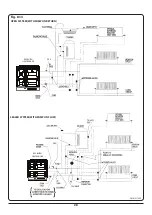

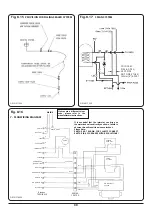

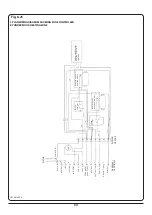

Fig. 8.3

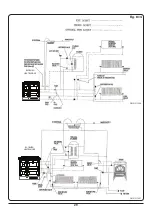

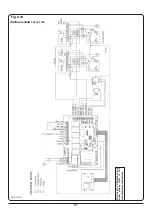

Fig. 8.4

DESN 517984

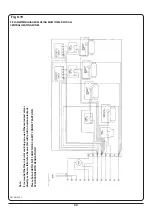

DESN 517985