EN

9

10. RESIDUAL RISKS

11. INSTALLATION AND USE

Even though the cutting unit is safe, operators must pay attention to preserve their and other

people’s safety.

At the end of the working operations, motor and metal parts could be very hot.

The cutting blade can work even when the protective device is disassembled.

To install and use the cutting unit manually, proceed as follows:

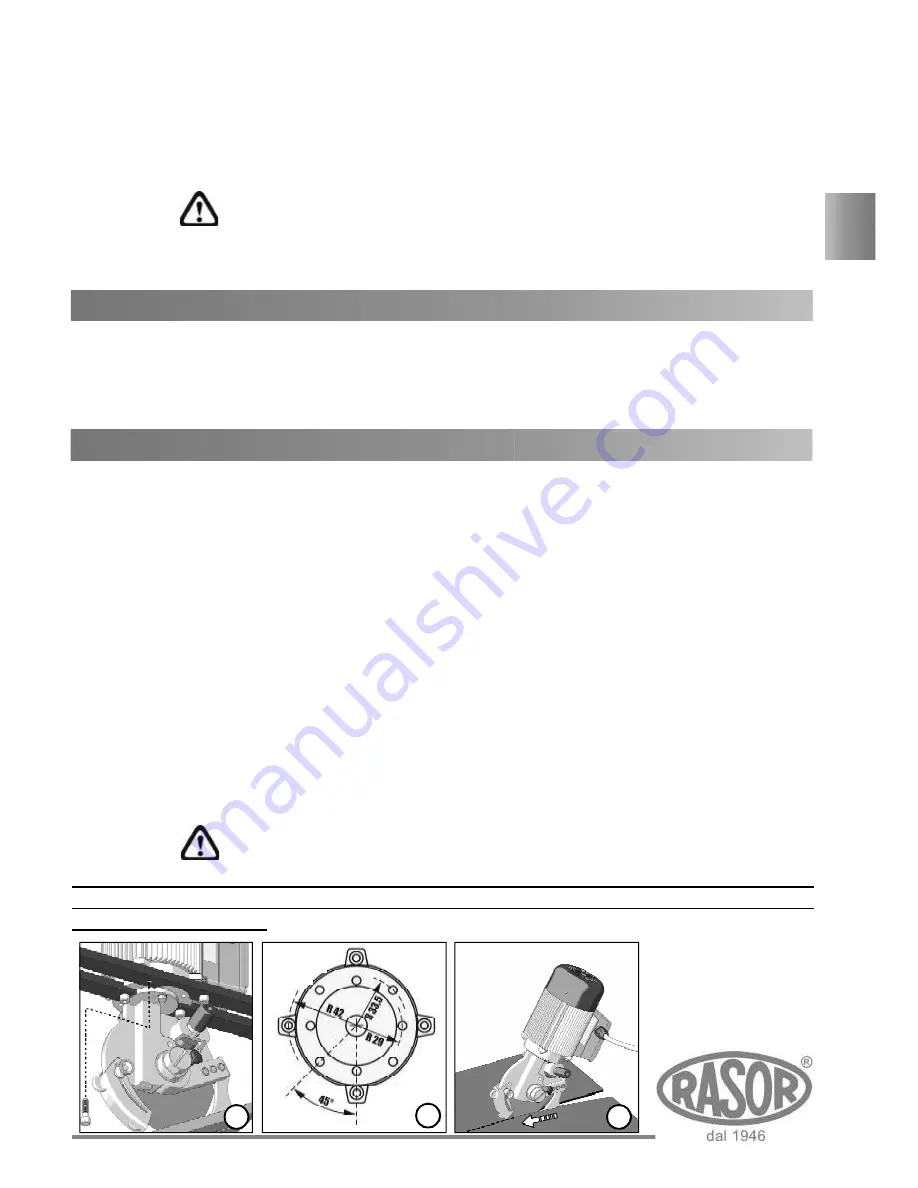

1) Fix the cutting unit on level squares or angles by means of four 5MA screws, by inserting

them in the eight holes located in the motor lower support (see pictures 4 and 5).

NOTE

The cutting unit can be installed in any position/angle: vertically, laterally and it can be turned

upside down. It is not compulsory for the aluminium base to touch the machine surface.

2) Lay the material to be cut;

3) Connect the cutting unit to the power supply;

4) Put the material on the cutting base (see picture 6);

5) Adjust the front mobile protection according to the thickness of the material to be cut;

6) Carry out the cutting operation.

NOTE

Cutting unit GRT12SM can work in a fixed position (the material has to be moved) or it can

move forward while the material is kept in the same position. Make sure the material to be cut

is properly stretched, preventing it from curling.

4

WARNING

Never use the two bolts which fix the motor to the cutting part to fasten cutting

unit GRT12SM. This operation may cause the motor shaft to break. In this case,

warranty is not valid.

5

Possible faulty earthing connections may cause unsafe working conditions. Possible damages

are not at RASOR

®

s.r.l. charge.

The power supply must be provided by a line protected against overcurrent by means of an

automatic (magnetothermal) switch or delayed fuses with a suitable dimensions. The current

allowing safety device enabling must be as low as possible considering the max. absorption

of the machine (see identification plate).

6

WARNING

The operator must install a disconnetting switch on the supply line in order to switch off the

machine, if necessary.