2

OM-65348-290 SELF-CONTAINED WORK-TOP FREEZER

INSTALLATION CHECKLIST

After the final location has been determined, refer to the following checklist prior

to start-up:

1. Check all exposed refrigeration lines to ensure that they are not kinked,

dented, or rubbing together.

2. Check that the condenser and evaporator fans rotate freely without striking

any stationary members.

3. Unit must be properly leveled; check all legs or casters to ensure they all are

in contact with the floor while maintaining a level work surface. Adjusting

bullet feet heights or shimming casters may be necessary if the floor is not

level. NOTE: Damage to equipment may result if not followed. Randell is

not responsible for damage to equipment if improperly installed.

4. Allow unit time to cool down to temperature. If temperature adjustments are

required, the control is located on the front panel. Confirm that the unit is

holding the desired temperature.

5. Refer to the front of this manual for serial number location. Please record this

information in your manual. It will be necessary when ordering replacement

parts or requesting warranty service.

6. Before putting in food, allow your unit to operate for approximately two (2)

hours so that interior of the unit is cooled down to storage temperature.

7. Check drawer to ensure the drawer slides freely and fully extends along with

seating into the cabinet properly when closed.

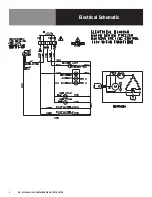

ELECTRICAL SUPPLY

Any wiring should be done by a qualified electrician in accordance with all

national and local electrical codes. A properly wired and grounded outlet will

assure proper operation. Please consult the data tag attached to the compressor

to ascertain the correct electrical requirements. Supply voltage and amperage

requirements are located on the serial number tag.

OPERATION

Allow unit to operate for approximately two (2) hours before placing in food.

AMBIENT CONDITIONS

Unit is designed for normal operating temperatures between 70° F (21°C) - 86°F

(32°C). Operating outside of those temperatures may cause premature product

wear or failure.

Randell has attempted to preset the temperature control to ensure that your

unit runs at an optimum temperature, but due to varying ambient conditions,

including elevation, food type and your type of operation, you may need to alter

this temperature using control adjustment until desired temperature is reached.

DANFOSS CONTROLLER OPERATION

LED

FUNCTION

Compressor energized & Evaporator fan de-energized

Defrost in progress

Fans delay after defrost completion

Evaporator fan energize

An alarm is occurring

ºC / ºF

Temperature unit

POWER ON / OFF

MANUAL DEFROST

CHANGE SET POINT

POWER ON / OFF:

Press and hold the power button until LED display turns On / Off

MANUAL DEFROST:

Press and hold “Defrost” Button

CHANGE SET POINT:

To raise temperature

IMPORTANT - READ FIRST - IMPORTANT

INTERIOR EVAPORATOR COVER

EXTERIOR OF UNIT

RISK OF FIRE OR EXPLOSION.

FLAMMABLE REFRIGERANT USED.

DO NOT USE MECHANICAL DEVICES

TO DEFROST REFRIGERATOR. DO NOT

PUNCTURE REFRIGERANT TUBING.

RIESGO DE INCENDIO O EXPLOSIÓN. REFRIGERANTE INFLAMABLE UTILIZADO. NO

UTILICE DISPOSITIVOS MECÁNICOS PARA DESCONGELAR EL REFRIGERADOR. NO

PERFORE LA TUBERÍA DEL REFRIGERANTE.

RISQUE D’INCENDIE OU

D’EXPLOSION.

INFLAMMABLE

RÉFRIGÉRANT UTILISÉ.

NE PAS UTILISER DE

DISPOSITIFS

MÉCANIQUES POUR

DÉGIVRER LE

RÉFRIGÉRATEUR. NE

FAIRE AUCUN TUBE

RÉFRIGÉRANT DE

PONCTION.

DANGER

SB6.1.2

WARNING ALERTE

CAUTION ATTENTIÓN

DO NOT REMOVE PANEL - HIGH VOLTAGE -

QUALIFIED PERSONNEL ONLY

NE PAS RETIRE LE PANNEAU - HAUTE TENSION -

PERSONNEL QUALIFIÉ SEULEMENT

NO RETIRE EL PANEL - ALTA TENSIÓN -

CALIFICADO PERSONAL

MOVING PARTS, DO NOT OPERATE

WITH COVER REMOVED

PIÉCES MOBILES NE PAS FAIRE

FONCTIONNER SANS COUVERCLE

LAS PIEZAS DE MOVIMIENTO NO FUNCIONAN

CON LA CUBIERTA RETIRADA

PP LBL1701 REV B

LABEL DIMENSION: 9 in x 3.25 in

RISK OF FIRE OR EXPLOSION.

DISPOSE OF PROPERLY IN

ACCORDANCE WITH FEDERAL OR

LOCAL REGULATIONS.

FLAMMABLE REFRIGERANT USED.

PRECAUCIÓN

RIESGO DE INCENDIO O EXPLOSIÓN. DESÉCHELO ADECUADAMENTE CONFORME

A REGLAMENTOS FEDERALES O LOCALES. REFRIGERANTE INFLAMABLE UTILIZADO.

MISE EN GARDE

RISQUE

D’INCENDIE OU

D’EXPLOSION. ÉLIMINER

(or DISPOSER)

CORRECTEMENT

CONFORMÉMENT AUX

RÉGLEMENTATIONS

FÉDÉRALES OU LOCALES.

RÉFRIGÉRANT

INFLAMMABLE UTILISÉ.

SB6.1.4

LABEL DIMENSION: 6 in x 2.75 in

PP LBL1704 REV B

CAUTION

RISK OF FIRE OR EXPLOSION DUE TO

PUNCTURE OF REFRIGERANT TUBING; FOLLOW

HANDLING INSTRUCTIONS CAREFULLY.

FLAMMABLE REFRIGERANT USED.

PRECAUCIÓN

RIESGO DE INCENDIO O EXPLOSIÓN DEBIDO A LA PERFORACIÓN DE LA TUBERÍA DE

REFRIGERANTE; SIGA CUIDADOSAMENTE LAS INSTRUCCIONES DE MANEJO. REFRIGERANTE

INFLAMABLE UTILIZADO.

MISE EN GARDE

RISQUE

D’INCENDIE OU

D’EXPLOSION EN RAISON

DE LA PERFORATION DU

TUBE RÉFRIGÉRANT;

SUIVEZ ATTENTIVEMENT

LES INSTRUCTIONS DE

MANIPULATION.

RÉFRIGÉRANT

INFLAMMABLE UTILISÉ.

CAUTION

SB6.1.5

PP LBL1705 REV B

LABEL DIMENSION: 6.25 in x 2.8 in

RISK OF FIRE OR EXPLOSION. FLAMMABLE

REFRIGERANT USED. CONSULT REPAIR MANUAL

/ OWNER’S GUIDE BEFORE ATTEMPTING TO

INSTALL OR SERVICE THIS PRODUCT. ALL

SAFETY PRECAUTIONS MUST BE FOLLOWED.

PRECAUCIÓN

RIESGO DE INCENDIO O EXPLOSIÓN. REFRIGERANTE INFLAMABLE UTILIZADO. CONSULTE EL MANUAL DE REPARACIÓN /

MANUAL DEL USUARIO ANTES DE INSTALAR O REPARAR ESTE PRODUCTO. DEBEN SEGUIRSE LAS PRECAUCIONES DE SEGURIDAD.

MISE EN GARDE

RISQUE

D’INCENDIE OU

D’EXPLOSION. RÉFRIGÉRANT

INFLAMMABLE UTILISÉ.

CONSULTER LE MANUEL DE

RÉPARATION / GUIDE DE

L’UTILISATEUR AVANT

D’ESSAYER D’INSTALLER OU

DE RÉPARER CE PRODUIT.

TOUTES LES PRÉCAUTIONS

DOIVENT ÊTRE RESPECTÉES.

SB6.1.3.b

PP LBL1703 REVB

LABEL DIMENSION: 7.5 in x 5.36 in

SB6.1.3.a

RISK OF FIRE OR EXPLOSION. FLAMMABLE

REFRIGERANT USED. TO BE REPAIRED ONLY

BY TRAINED SERVICE PERSONNEL. DO NOT

PUNCTURE REFRIGERANT TUBING.

PELIGRO

RIESGO DE INCENDIO O EXPLOSIÓN. REFRIGERANTE INFLAMABLE UTILIZADO. DEBE SER REPARADO

SOLAMENTE POR PERSONAL DE SERVICIO CAPACITADO. NO PERFORE LA TUBERÍA DEL REFRIGERANTE.

DANGER

RISQUE

D’INCENDIE OU

D’EXPLOSION.

RÉFRIGÉRANT

INFLAMMABLE UTILISÉ.

POUR ÊTRE RÉPARÉ QUE

PAR UN TECHNICIEN

QUALIFIÉ. NE PAS

PERFORER LE TUBE

RÉFRIGÉRANT.

CAUTION

DANGER

NEAR EXPOSED REFRIGERANT TUBING

NEAR MACHINE COMPARTMENT AND NAMEPLATE