Note:

These adjustments are normally made only

when related parts have been installed or the

machine is knocked out of alignment. Inspect all

other adjustments before resorting to realigning

the needle and awl.

Alignment of the Needle - R

IghT

TO

L

eFT

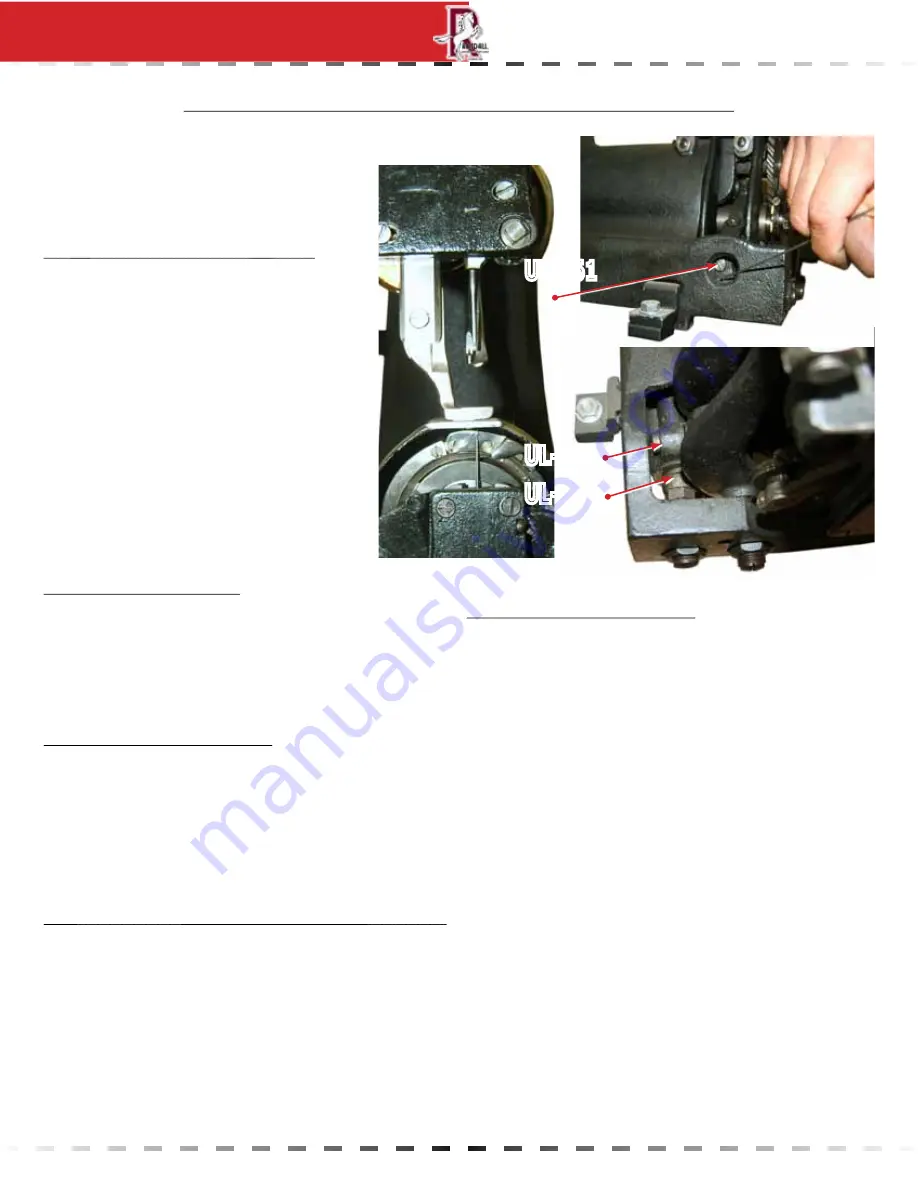

• Remove the bottom cover UL-300/UL-301. This is on the bottom left side of the machine. You will see 3 nuts (UL-10),

once you take off the cover. The two center nuts will adjust the needle left or right.

• First, on the bottom left of the machine open the screw (UL-13) on the needle disk (UL-214). You, then need to open the

screw (UL-161) on the back of the machine (see the instruction section, “Adjusting The Needle Front To Back”). You do

this so when you perform the following adjustments, the machine will not bind. First, you need to open the two nuts (UL-

10), both on the front end of the casting and on the back end of the casting.

• NOTE: You will need only a slight adjustment here. If you want to move the needle to the left, just open the right bolt

(Ul-11) (of the three on the front of the casting) counter-clockwise 1/8 turn and then turn the left screw equally. You need

to move the bolts on the back end of the casting equally clockwise. Also, once adjusted, tighten all the nuts (UL-10), both

front and back ends.

• NOTE: when you move the needle left or right, you need to re-adjust the alignment of the shuttle point (UL-276) to the

needle. If the thread breaks and jumps inside of the bobbin, there are 2 reasons for this: A) You do not have enough

R

andall

UnIOn

l

Ock

-S

tItch

Alignment

Since 1858

technical Support

1-800-327-9420

12

Inspecting the Alignment

Note:

Before inspecting or changing the

alignment, insure that the needle or awl are not

bent.

•

when the needle and awl are perfectly

aligned, the needle should comes up

through the material without flexing or

hitting the sides of the awl hole.

•

To see the alignment, set a piece of paper

under the foot. Turn the hand wheel

toward you until the awl makes a hole

in the paper. Again turn the hand wheel

and watch the position of the needle as it

ascends through the awl hole.

•

If the needle appears to rip the paper

either in front or back of the awl hole,

adjust the alignment with the procedure

below.

Needle - F

RONT

TO

B

ACk

Before changing this alignment, make sure the awl is ad-

justed properly.

• Turn the hand wheel until the needle starts to ascend.

• Locate the cutout, on the bottom rear corner, left side of

the machine.

• Insert a screwdriver through the cut out and loosen screw

Ul-161.

• Apply a wrench to the end of the nut, located to the left of

the bracket.

• This nut is part of the rocking shaft (UL-223). If you turn

the wrench away from you, the needle will move forward.

If you move the wrench towards you, the needle will move

back.

• After setting, tighten screw UL-161.

A

LIgNMeNT

OF

The

N

eedLe

ANd

A

wL

UL-161

UL-223

UL-161

Awl - F

RONT

TO

B

ACk

Both the needle and awl should be approximately 1/16” from

the front edge of the hole in the needle plate.

•

The awl bar can be aligned by adjusting the gibs (UL-

77/78) with the slotted screws on the front face of the

head.

•

There should be no play awl bar, but do not over tighten

the gibs which will cause the action to bind

Needle - F

RONT

TO

B

ACk

•

If there is play in the needle bar adjust the gibs (UL-

197r/l). Do not over tighten the gibs.

•

Adjust the position of the shuttle housing (UL-235), by

loosening the four nuts (Ul-229) and move the housing

forward or back by turning the screws Ul-237.

•

once the needle and awl is approximately 1/16” from the

front edge of the hole in the needle plate, secure the nuts

(Ul-229).